High-Precision 5-Axis CNC Machining Services for Aluminum Engine Housings

Release time:

2025-10-30 17:57

Precision in Motion: 5-Axis CNC Machining of Automotive Engine Housings

In today’s automotive manufacturing landscape, precision engineering is no longer an advantage — it’s a necessity. Components like engine housings, gearboxes, and powertrain casings demand micron-level accuracy, surface perfection, and structural strength to support high-performance vehicles.

At GD Prototyping, we specialize in 5-axis CNC machining for complex aluminum parts, helping automotive innovators bring their ideas to life with unmatched precision and speed.

What Makes 5-Axis CNC Machining Essential for Engine Housings

Unlike conventional 3-axis machining, 5-axis CNC technology allows cutting tools to move in five different directions simultaneously. This capability enables us to:

Machine deep cavities and complex geometries in a single setup

Maintain tight tolerances on multi-surface parts

Achieve exceptional surface finishes without secondary operations

Reduce setup time and human error

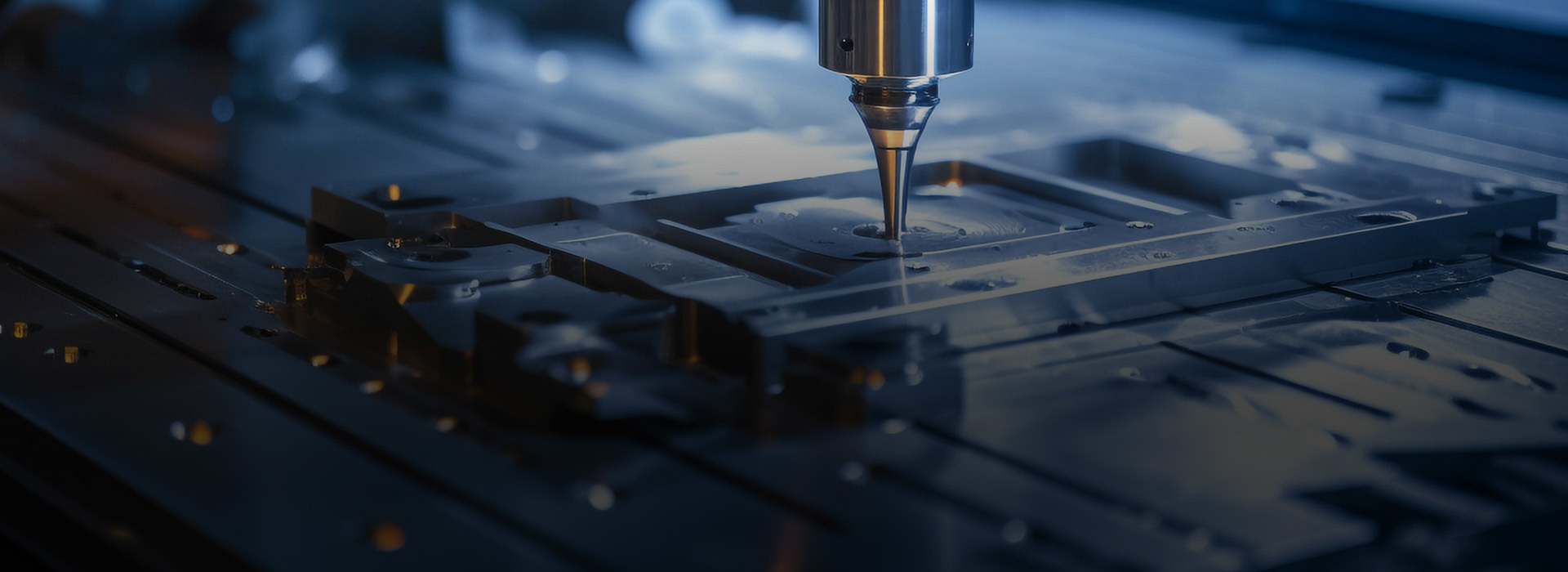

In the image above, our machining center is performing precision milling on an aluminum engine housing, with coolant ensuring thermal stability and tool longevity. Every rotation, feed rate, and toolpath is optimized by our engineers for efficiency and accuracy.

High-Precision Machining Meets Automotive Performance

Engine housings are not just protective shells — they form the structural backbone of an engine. Their accuracy directly impacts alignment, vibration control, and transmission efficiency.

Our 5-axis CNC machining centers are equipped with advanced spindle systems and high-speed controllers that deliver tolerances up to ±0.005mm. We use aerospace-grade aluminum alloys such as 6061-T6 and 7075-T6, providing the ideal balance between strength, thermal conductivity, and weight reduction — essential factors for modern electric and combustion vehicles.

Each part undergoes CMM inspection, ensuring dimensional accuracy before shipment. From prototype to production, we maintain consistent quality through our ISO-certified process control system.

From Concept to Completion: Custom CNC Machining Solutions

Whether you are developing a prototype for an EV motor housing or scaling up production for high-performance racing engines, GD Prototyping provides end-to-end support:

·DFM (Design for Manufacturability) Consultation

·Material Selection & Process Optimization

·Rapid Prototyping & Low-Volume Manufacturing

·Full Metrology and Quality Reports

Our engineering team collaborates closely with clients to reduce cost, shorten lead time, and improve manufacturability — without compromising precision.

Why Automotive Brands Choose GD Prototyping

1.Over 10 years of CNC machining experience in the automotive and aerospace industries

2.Advanced 5-axis and multi-axis machining centers

3.Expert team for complex part programming and verification

4.Fast global delivery and consistent communication

5.Proven reliability from prototype to mass production

6.Empowering Automotive Innovation with Precision Manufacturing

At GD Prototyping, we believe precision is the driving force behind innovation. Our advanced 5-axis CNC machining services enable automotive manufacturers to accelerate design validation, improve performance, and achieve production excellence.

From the first toolpath to the final inspection, we ensure every part reflects our commitment to quality and craftsmanship.

5-Axis CNC Machining,CNC Machining,CNC Engine,CNC Engine Housings,Precision parts

preceding page

Related News

2024-04-05