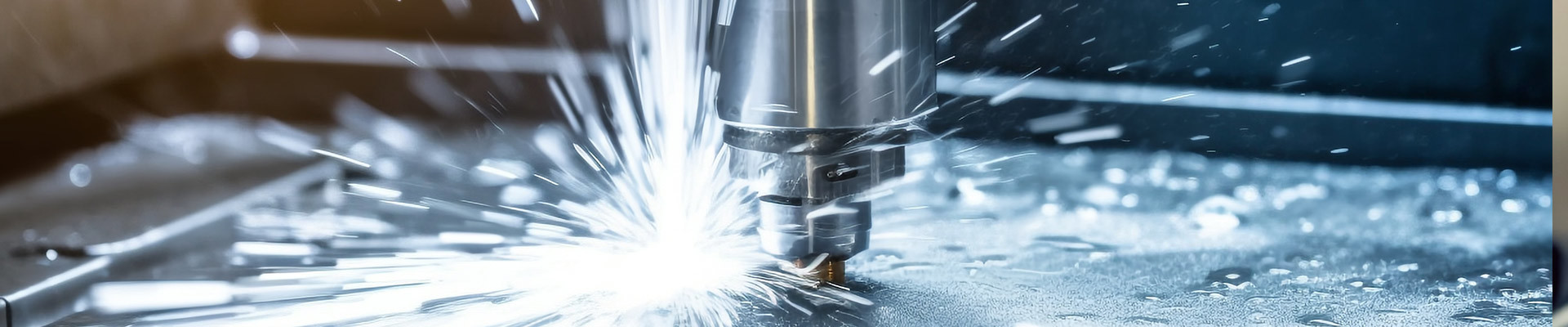

GD prototyping Lathe machining

Small error, high-precision processing can be achieved

CNC lathe is a common machining method that uses a lathe to cut the rotating workpiece to achieve the desired size and shape. Materials: metal materials, plastic materials, composite materials, cast iron, ceramics, etc. Advantages: high precision, high efficiency, wide application range, simple operation, low cost, good quality. Application areas: machinery manufacturing, hardware tools, automobile manufacturing, aerospace, electronic equipment, etc.

Advantages of Lathe machining

Productivity And Efficiency

CNC machinery can work continuously over any period of time without a break. This greatly increases productivity and efficiency

High Precision Tolerances

With computer software, the design of any given product only needs to be programmed once. The CNC machine can then perfectly replicate that design.

Flexibility

The software can be reprogrammed quickly and easily to produce different parts, allowing operations to keep up with shifting customer demands. And wide variety of material can be selected as well as kinds of surface finishes.

Capability

From one piece to more than 1,000 pcs can be finished by CNC Machining in short time without the need for investing in hard molding or expensive set ups.

Why Lathe machining with GD prototyping

Facilities

At GD prototyping, we have 5 modern manufacturing facilities in Dongguan, including a full complement of advanced computerized milling and turning centers, as well as grinding and Wire& Sinker EDM machining equipment.

Professional

We are best known for our expertise in 5 axis machining, precision manufacturing, we are dedicated to providing the manufacturing solutions for upscale industries like Aerospace,Medical,Semiconductor and Automotive fields, our milling spindle capabilities can be up to 40,000RPM. From prototypes to small batch production and productive mass production can be realized at here.

Solutions

Series Options: From 3 axis, 4 axis to 5 axis CNC milling and CNC turning we can provide you with most suitable manufacturing solutions for your projects.

One Stop Shop: Not only can we fabricate your parts but also a lot of post-processing treatment provided and from prototypes to the marketing products, all you can rely on us.

Competences

Processing improvement, cost improvement and machinery improvement are our core competences to ensure we stay current on the emerging technologies in the manufacturing industry.

Our Lathe machining Capabilities

CNC

Lathe machine

Headstock mobile CNC automatic lathe, economical turning and milling machine tool or longitudinal lathe. It is a precision processing equipment that can complete turning, milling, drilling, boring, tapping, engraving and other composite processing at the same time, and is mainly used for batch processing of precision hardware and special-shaped non-standard shaft parts.

CNC

Lathe

It can cut and process the inner and outer cylindrical surfaces of parts, inner and outer conical surfaces of arbitrary cone angles, complex inner and outer curved surfaces of revolution, and cylindrical and conical threads, and can also perform grooving, drilling, reaming, reaming and boring, etc.

Turning and milling

Compound machining is one of the most popular machining processes in the field of mechanical machining. It is an advanced manufacturing technology. Compound machining is to realize several different machining processes on one machine tool. The most widely used and most difficult compound machining is turning and milling compound machining. The turning and milling compound machining center is equivalent to a combination of a CNC lathe and a machining center.

Technical Information

3 axis CNC Milling

Maximum Part Size

Metal and plastic parts: 3,000mmX2,000mmX800mm

Minimum feature size: φ0.50mm

Maximum rotation speed: 12,000m/s

4 axis CNC Milling

Metal and plastic parts: 1,100mmX610mmX600mm

Minimum feature size : φ0.50mm

Maximum rotation speed: 24,000m/s

5 axis CNC Milling

Aluminium,Copper,Brass and Plastics : 1,000mmX800mmX600m

Minimum Feature size : φ0.50mm

Maximum rotation speed: 40,000m/s

CNC Turning

Maximum part size

Limitation Parameter (Metric)

Max swing diameter: 360~800 mm

Max cutting length: 270~1500 mm

Spindle bore: 45~100 mm

Rapid moving speed: 20 m/min

Spindle speed range: 50-4200 r/mm

Technical Information

3 axis 3+2 axis CNC Workshop

4 AXIS CNC Workshop

5 axis CNC Milling Roders

5-axis machining shop

CNC Lathe machine

CNC Machining workshop

Picture Display

We offer a wide range of CNC machining services including milling and turning of various materials, as well as drilling, tapping, EDM (Electrical Discharge Machining), and wire EDM.

Online Message

If you are interested in cooperation, please contact us immediately and we will give you feedback as soon as possible!