Precision 5-Axis CNC Machining for Complex Impellers

Release time:

2025-10-31 18:07

In today’s fast-evolving manufacturing world, the demand for precision-engineered components continues to rise across industries such as aerospace, automotive, energy, and industrial equipment. Among the most challenging parts to produce are impellers — components that require extreme accuracy, perfect balance, and flawless surface finishes to perform under high-speed, high-pressure conditions.

At GD Prototyping, we specialize in 5-axis CNC machining for complex impeller geometries and high-performance prototypes. Our advanced machining technology, engineering expertise, and strict quality standards ensure every impeller we manufacture meets the most demanding requirements of modern industry.

What Is 5-Axis CNC Machining and Why Does It Matter?

Traditional 3-axis machining is limited to movement along the X, Y, and Z axes. However, 5-axis CNC machining adds two additional rotational axes — allowing the cutting tool to approach the workpiece from virtually any direction.

This capability provides major advantages for impeller machining:

Single setup machining: Reduces repositioning, increasing accuracy and consistency.

Complex surface capability: Enables efficient machining of curved blades and deep cavities.

Superior surface finish: Smooth, continuous tool paths eliminate machining marks and reduce polishing needs.

Faster production: Reduces cycle time and improves repeatability, ideal for both prototypes and low-volume production.

By leveraging 5-axis machining, GD Prototyping delivers tight tolerances and complex geometries that traditional machines simply can’t achieve.

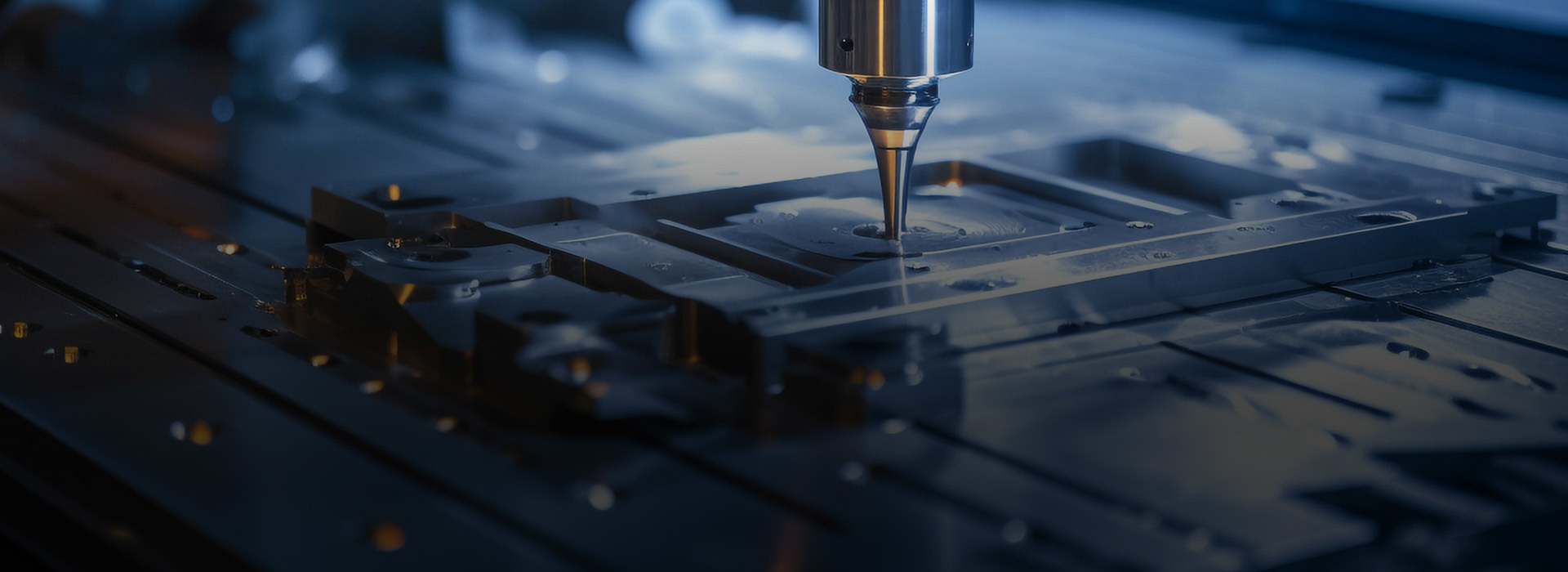

Precision Impeller Machining: Where Engineering Meets Art

The impeller shown above is one of our showcase projects — a multi-blade, high-performance component machined entirely from solid metal. Each blade’s thickness, curvature, and angle must be controlled within microns to maintain perfect dynamic balance during high-speed operation.

Our engineers use advanced CAM programming and simulation to generate optimized tool paths, ensuring efficient material removal while minimizing stress and vibration. Combined with real-time process monitoring, this guarantees each part is dimensionally accurate and mechanically reliable.

Material Expertise and Surface Quality

At GD Prototyping, we work with a wide range of materials to meet the needs of different industries:

Aluminum alloys (6061, 7075, etc.) – Lightweight and corrosion-resistant, ideal for automotive and aerospace applications.

Titanium alloys – High strength-to-weight ratio and excellent fatigue resistance for extreme environments.

Stainless steels – Durable, heat-resistant, and suitable for industrial-grade impellers.

Our engineers fine-tune every aspect of the process — from spindle speeds and feed rates to coolant flow and tool geometry — to achieve optimal cutting conditions. The result is a high-quality machined surface that requires little to no post-processing, improving efficiency and reducing cost.

From Rapid Prototyping to Small-Batch Production

GD Prototyping is more than just a machining provider — we are your manufacturing partner from concept to completion.

Whether you need a one-off prototype for aerodynamic testing or a small-batch production run, we provide full-service solutions that include:

DFM (Design for Manufacturability) review

Process optimization and tolerance analysis

Custom fixture and tooling design

Surface treatments and coating options

Quality control with CMM inspection and material certification

Our flexible production capabilities allow us to respond quickly to tight schedules while maintaining the highest standards of precision and quality.

Industries We Serve

Our 5-axis CNC impeller machining services are trusted by clients across multiple sectors:

Aerospace & Aviation – Compressor impellers, turbine rotors, jet engine components

Automotive & Motorsport – Turbocharger impellers, high-performance engine parts

Energy & Power Generation – Pump impellers, gas turbine blades

Industrial Equipment – Fans, compressors, and custom rotating components

Every industry has unique challenges — and we tailor our machining approach to deliver parts that meet their specific performance, durability, and safety standards.

Quality Assurance at Every Step

Quality is the foundation of everything we do. Each impeller produced by GD Prototyping goes through comprehensive inspection and testing, including:

Coordinate Measuring Machine (CMM) dimensional inspection

Surface roughness measurement

Dynamic balancing

Visual and manual inspection by skilled technicians

These rigorous quality checks ensure that every part meets or exceeds our clients’ specifications and international manufacturing standards.

Why Choose GD Prototyping for Your CNC Machining Projects?

✅ Advanced 5-axis CNC equipment for complex geometries

✅ Experienced engineering team for technical design support

✅ High material compatibility (aluminum, titanium, stainless stee

Related News

2024-04-05