High-Precision CNC Machining & Rapid Prototyping Services

Release time:

2025-10-22 18:19

In today’s fast-paced manufacturing world, the difference between success and failure often lies in precision, speed, and consistency.

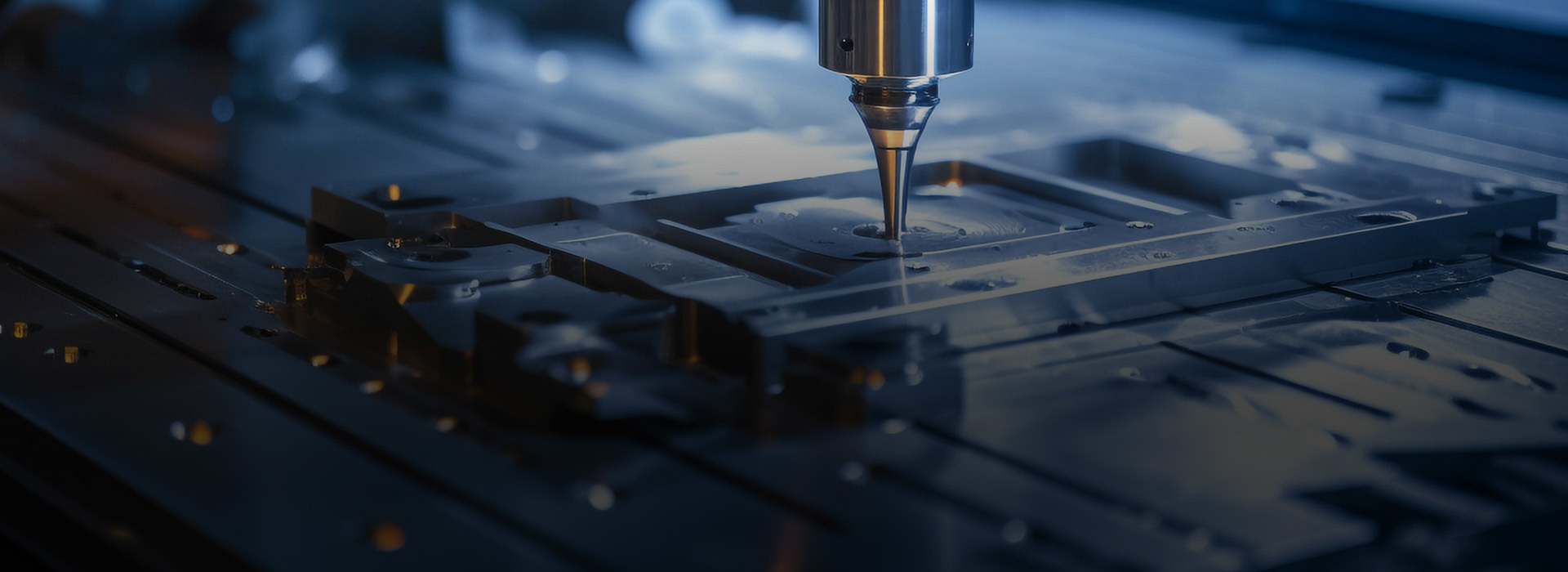

At GD Prototyping, we specialize in high-precision CNC machining and rapid prototyping services — transforming your 3D designs into real, functional parts with unmatched accuracy and efficiency.

Whether you need a single prototype for design validation or a small production batch for pre-launch testing, GD Prototyping provides the cutting-edge manufacturing capabilities you can rely on.

Why CNC Machining Matters in Modern Product Development

CNC machining remains the cornerstone of modern product manufacturing due to its precision, repeatability, and material versatility.

Unlike additive manufacturing or manual processing, CNC machining allows engineers and designers to create complex geometries and tight-tolerance components with superior mechanical properties.

Our 5-axis CNC machining centers give us the flexibility to handle even the most demanding geometries — multi-surface milling, deep cavity machining, and undercut structures — all in one setup.

This not only improves precision but also shortens lead time and reduces costs for our clients.

Our Advanced CNC Capabilities

At GD Prototyping, technology and craftsmanship go hand in hand.

Our workshop is equipped with high-performance AFMING spindles and RENISHAW probe systems, ensuring every cut, edge, and surface meets the highest international standards.

Capabilities include:

3-axis, 4-axis, and 5-axis CNC machining

Tight tolerances up to ±0.005mm

Surface finishes: brushed, anodized, sandblasted, mirror polished, and more

High-speed machining for complex aluminum and steel parts

In-house CMM inspection and full dimensional reports

We serve industries such as aerospace, automotive, robotics, medical devices, and electronics, where precision and reliability are non-negotiable.

Rapid Prototyping — From Design to Reality in Days

Time-to-market is everything.

Our rapid prototyping services empower designers and engineers to move from concept to functional prototype within just 3–5 days.

We work with a wide range of materials including:

Metals: Aluminum 6061/7075, Stainless Steel, Copper, Titanium

Plastics: ABS, POM, PC, PMMA, Nylon, PEI, and more

With advanced programming and optimized toolpaths, we minimize lead time while maintaining high dimensional accuracy and exceptional surface quality.

Each prototype is carefully inspected before shipment — ensuring the final product fits, functions, and performs exactly as designed.

Trusted by Global Innovators

Our CNC machining and prototype manufacturing services are trusted by clients in the United States, Germany, Japan, India, and Vietnam.

We have successfully supported OEMs, startups, and R&D teams with precision parts that meet strict functional and aesthetic requirements.

By integrating engineering expertise, digital workflow, and international logistics, GD Prototyping ensures that every customer — wherever they are — receives professional, consistent, and on-time manufacturing support.

Why Choose GD Prototyping?

✅ Over 10 years of CNC machining experience

✅ Advanced 5-axis machining centers

✅ ISO-standard quality control with CMM inspection

✅ Rapid quotation and DFM (Design for Manufacturability) feedback

✅ Flexible one-stop service: from prototype to low-volume production

Our goal is simple: to help you turn ideas into precision-engineered reality.

Get a Free CNC Machining Quote Today

Upload your CAD or 3D files (STEP, IGS, STL, etc.) and receive a professional quotation and manufacturability analysis within 24 hours.

At GD Prototyping, we don’t just make parts —

we bring your innovation to life, with accuracy you can measure and quality you can feel.

Contact us today

to start your next project with confidence.

Related News

2024-04-05