Production Capabilities

Our project management team consists of skilled production and engineering personnel who are dedicated to meeting specific delivery needs. This level of dedication means that machining start times are adhered to and that integrated systems and lean-manufacturing-based project management tools are utilized to track the progress of each order.

Injection molding is a manufacturing process for producing plastic parts by injecting molten material into a mould,which is most typically used in mass-production processes where the plastic part is being created thousands or even millions of times in succession.

Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mould cavity. The mould cavity is created using two hardened tool steel dies which have been machined into shape, also for producing large quantity.

Precision casting is a process in which the metal is melted into a liquid meeting certain requirements and poured into the casting mold. After cooling, solidification and cleaning, the casting with predetermined shape, size and performance can be obtained.

What is Vacuum Casting

At GD prototyping, we specialize in producing high-quality plastic injection molded parts and mold tools. We offer machining and finishing services to make tools from a variety of materials, and can produce 50 to 100,000+ finished parts in a wide variety of plastics. With advanced material verification and quality processes we can ensure your tools and parts exceed your expectations.

Advantages of Injection Molding

◆ A wide variety of plastic materials

◆ Large volume in short timeline

◆ Stable and reliable process

◆ Long term mold and for production

◆ Premium quality

Injection Molding Capabilities

01

Rapid tooling

Most choice for the low volume production, using the aluminum inserts with a life time of up to 20,000 run, typically 1-2 weeks, it can reduce leadtime .

02

Production tooling

A stable and reliable mold process for mass production,machined in typically 3-4 weeks, with a life time up to 100,000.

03

Multi-cavity molds

Multiple identical cavities are machined into the mold tool. This allows for more parts to be produced simultaneously per shot, not only leveraging the manufacturing efficiency but also minimizing the unit costs.

04

Overmolding

Adding an additional layer of material over an already existing molded piece or part.

What is Vacuum Casting

| Name | Description |

| Minimum order quantity | 200 runs |

| Mold material | Tool Steel P20, Carbon Steel S50C, Aluminum |

| Mold types | Rapid tooling, production tooling |

| Mold storage | Minimum 2 years and we will do the maintenance for the mold. |

| Mold lead time | 2-3 weeks (Rapid tool), 4-5 weeks (Production tool) |

| Quality assurance | DFM Analysis, Moldflow, CAE, Control Plan, PSW Inspection reports included, full dimensional report and material certifications available upon request, PPAP submitted after starting the production. |

| Sample verification program | Similar to First Article Inspection, you will receive 2 sets of parts upon the machining of the mold to test fit before continuing with full production. |

| Mold remachining | We can remachine the molds should any changes be required, changes to be reviewed on a case by case basis. |

| Reorders | Unit price is based on the quantity required for the reorder with an additional set up fee of $150/€120. |

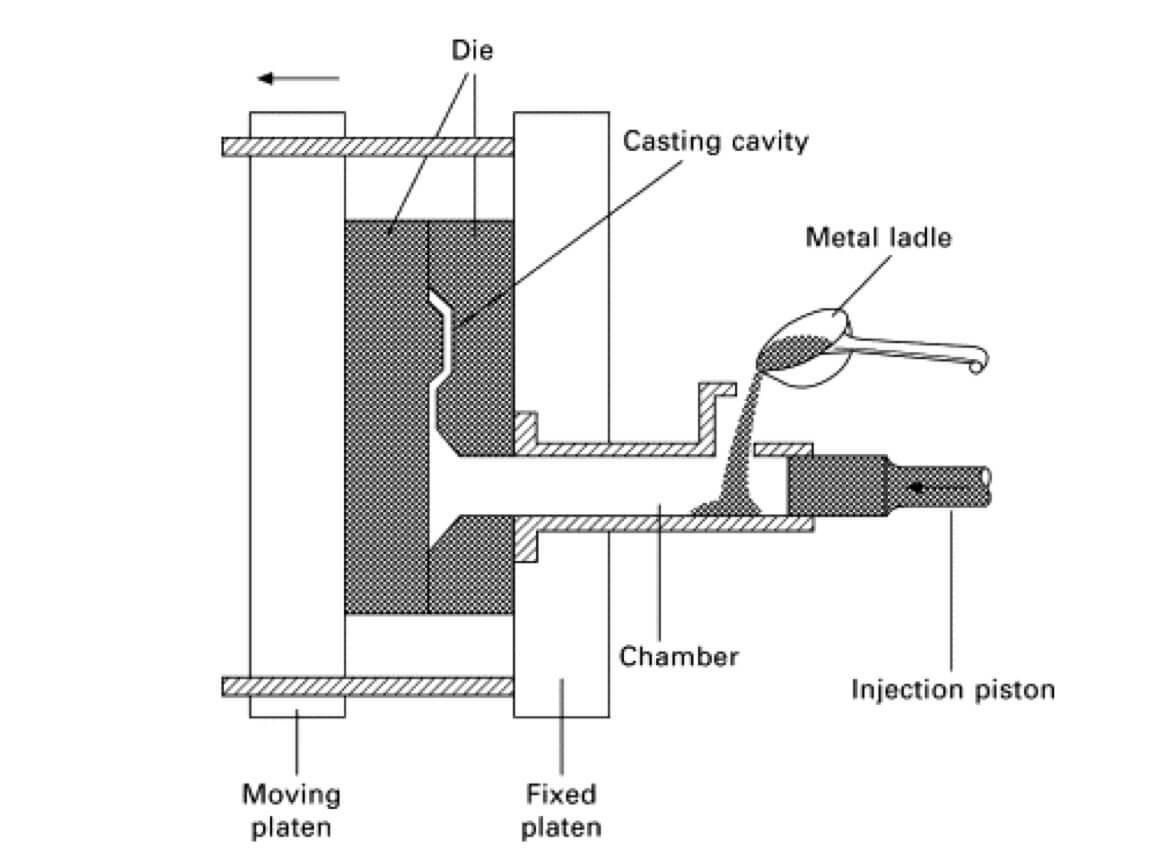

Die Casting

Die casting is generally the lowest cost method for producing complex-shaped components from aluminium alloys, and so rheocasting should also have the potential for low cost production. Die-casting is an economical way of producing large quantities of complicated shaped products of light metals with high precision. Melted metals are introduced at a high speed into the water-cooled metal die or mold through an injection process. The molten metal turns into a solid when in contact with the cool water. When the solidification and mold casting process has completed, the mold is opened and the ejection of parts initiated via a mechanical activation of the ejector pins. The die is subsequently exposed to air, sprayed with a lubricant, closed, and molten metal injected once again into the die to complete the cycle.

Die Casting Capabilities

Rapid Tooling

Most choice for the low volume production, using the aluminum inserts with a life time of up to 20,000 run, typically 1-2 weeks, it can reduce leadtime .

Low-Pressure Die Casting

in which the metal is forced into the mold with air pressure for mass production,machined in typically 3-4 weeks, with a life time up to 100,000

High-Pressure Die Casting

In which a hydraulic ram is used to inject the molten metal into the die at extremely high pressures not only leveraging the manufacturing efficiency but also minimizing the unit costs.

Gravity Permanent Mold Casting

This process use the metal die in combination with a gravity-fed metal delivery system. This combination lowers the overall cost of the process while taking advantage of the higher cooling rate of the metal die. The advantages and limitations of this system are similar to those of the LP permanent mold systems.

Picture Display

We offer a wide range of CNC machining services including milling and turning of various materials, as well as drilling, tapping, EDM (Electrical Discharge Machining), and wire EDM.

Online Message

If you are interested in cooperation, please contact us immediately and we will give you feedback as soon as possible!