Advantages of CNC machining transparent parts

Release time:

2025-05-06 17:58

CNC machining technology plays an important role in modern manufacturing, and its application in machining transparent parts is particularly prominent. The advantages of CNC machining transparent parts are its high precision, high efficiency, high customization and wide applicability, which makes it widely used in many fields, such as aviation, medical, optics and consumer electronics.

Advantages of CNC machining transparent parts

1. High-precision machining

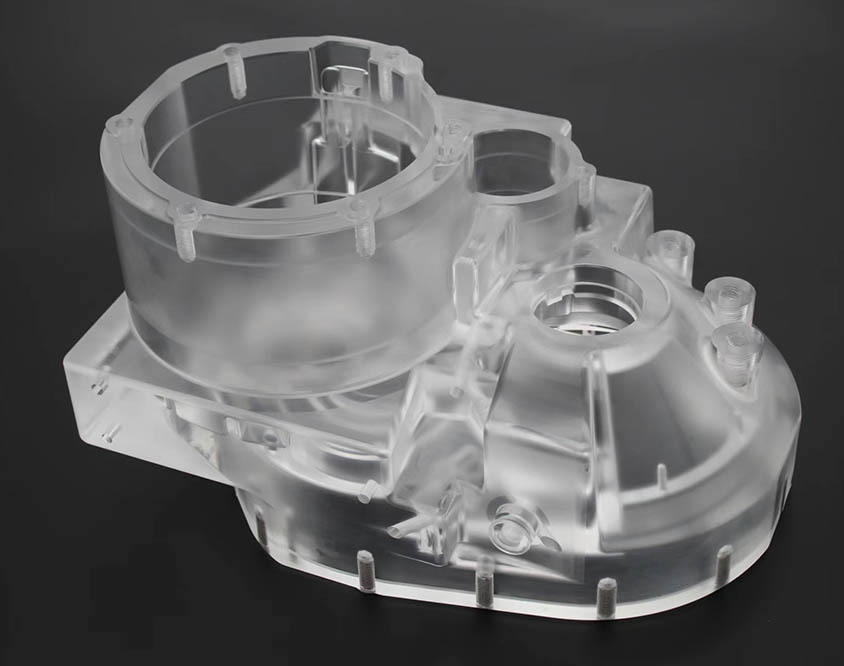

CNC machining technology can achieve high-precision machining by precisely controlling the movement of machine tools through computers. For transparent parts, high-precision machining can ensure that the surface of the parts is smooth and flawless, improving the overall quality of the product. In addition, CNC machining can also achieve the machining of complex shapes, making the design of transparent parts more flexible and diverse.

2. High-efficiency production

CNC machining uses equipment with a high degree of automation to achieve efficient production. When machining transparent parts, CNC machine tools can quickly complete cutting, grinding, drilling and other processes, greatly improving production efficiency. In addition, CNC machining can also achieve mass production to meet the market's large-scale demand for transparent parts.

3. High degree of customization

CNC machining technology can be highly customized according to customer needs. When machining transparent parts, precise machining can be performed according to the design requirements of the product to achieve personalized customization of the product. This gives CNC machining a greater competitive advantage in the field of transparent parts manufacturing.

4. Wide applicability

CNC machining technology is applicable to a variety of materials, including transparent materials. Whether it is plastic, glass or other transparent materials, CNC machining can achieve efficient and precise machining. This gives CNC machining a wide range of applications in the field of transparent parts manufacturing.

5. High-quality surface quality

CNC machining can ensure that the surface quality of transparent parts reaches a high level. Through precise machining and control, defects such as scratches and burrs on the surface of the parts can be avoided, and the appearance quality of the product can be improved.

6. Strong design flexibility

CNC machining can realize the complex shape machining of transparent parts, making product design more flexible and diverse. This gives CNC machining a greater degree of design freedom in the manufacturing industry and can meet the different needs of customers.

There are many application cases of CNC machining in the field of transparent parts manufacturing, such as transparent windows in the aviation field, transparent test tubes in the medical field, lenses in the optical field, and transparent mobile phone cases in the consumer electronics field. These cases fully demonstrate the advantages and application potential of CNC machining in the field of transparent parts manufacturing.

CNC machining transparent parts has the advantages of high precision, high efficiency, high customization, wide applicability, high surface quality and strong design flexibility. These advantages make CNC machining have broad application prospects in the field of transparent parts manufacturing. With the continuous development of science and technology, CNC machining technology will continue to improve in the future, bringing more possibilities for transparent parts manufacturing.

CNC machining transparent parts,CNC transparent parts,CNC machining,CNC plastic

preceding page

preceding page

Related News

2024-04-05