Metal 3D printing principles and applications

Release time:

2025-04-30 15:25

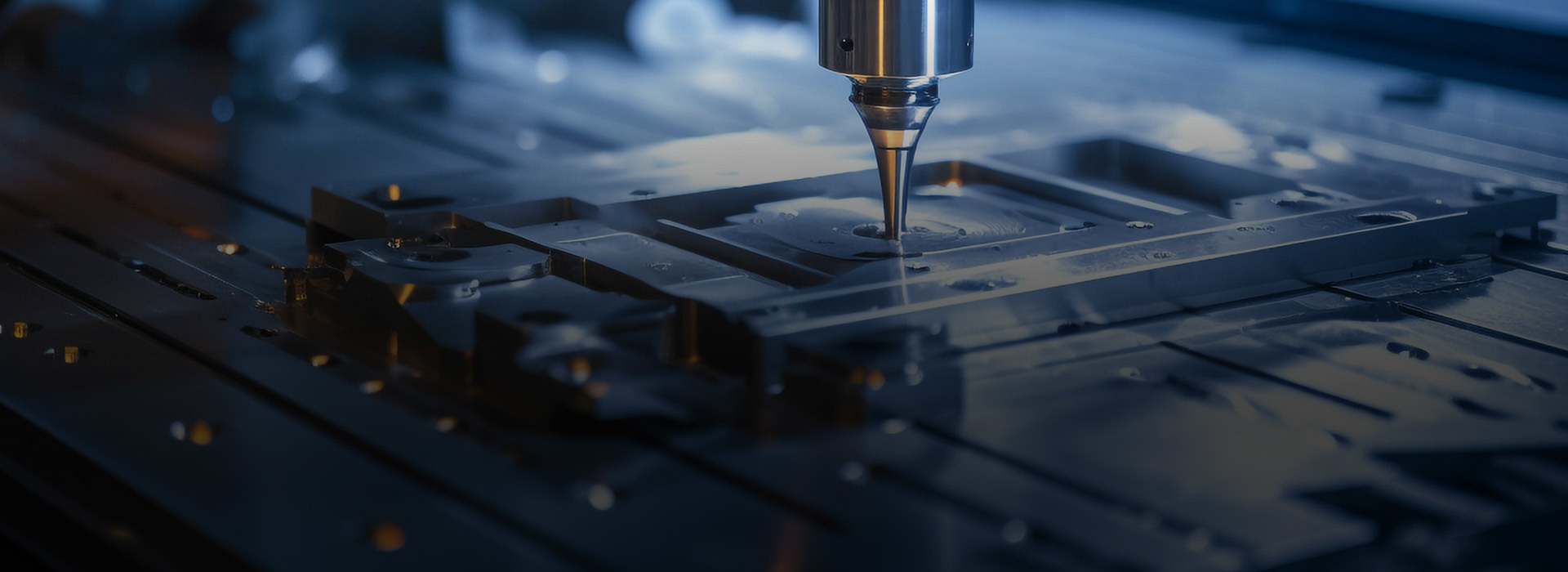

Metal 3D printing, also known as metal additive manufacturing, is a process of stacking metal materials layer by layer to create actual objects through digital technology. Its basic principle is driven by a computer-aided design (CAD) model, and metal powder is melted and solidified layer by layer through a high-energy laser beam, electron beam or heat source to finally form the desired product.

Classification of metal 3D printing technology

1. Selective laser melting (SLM): Metal powder is selectively melted by a laser beam to form the outline of the part, and then stacked layer by layer to finally obtain a complete metal part.

2. Metal powder jetting (Metal Powder Jetting): Metal powder is sprayed onto the workbench, and the powder is melted into the desired shape by heat or laser, and then stacked layer by layer to form a part.

3. Electron beam melting (Electron Beam Melting, EBM): Metal powder is melted using a high-energy electron beam, which is suitable for the production of high-performance metal material parts.

Metal 3D printing technology has a wide range of applications, mainly including the following aspects:

1. Aerospace: Used to manufacture high-performance parts such as engine components and aerospace structural parts.

2. Automobile manufacturing: used to produce automobile parts, such as engine parts, chassis structures, etc.

3. Medical devices: manufacture customized medical devices, such as dental implants, orthopedic repair parts, etc.

4. Jewelry manufacturing: produce personalized and customized jewelry.

5. Industrial field: used to manufacture complex parts such as molds, turbine blades, and piping systems.

Advantages of metal 3D printing

1. Save materials: Through additive manufacturing, only the required parts are printed, which greatly improves the material utilization rate. The material utilization rate of additive manufacturing can reach more than 90% (traditional processing may be less than 50%)

2. High customization: It can produce customized products that meet personalized needs, suitable for small batches and personalized needs (such as medical implants, aerospace customized parts)

3. High production efficiency: simplify the manufacturing process and reduce processing time.

4. Complex geometric molding: It can manufacture internal flow channels and lightweight topological structures that cannot be achieved by traditional processes.

Common metal materials

Titanium alloy (Ti-6Al-4V): used for biocompatibility and high-strength and lightweight requirements.

Stainless steel (316L, 17-4PH): corrosion-resistant, suitable for industrial parts.

Aluminum alloy (AlSi10Mg): lightweight structural parts.

Nickel-based high-temperature alloy (Inconel 718, 625): high temperature resistant, used in aircraft engines.

Cobalt-chromium alloy: wear-resistant, suitable for dental and joint implants.

However, metal 3D printing also faces some challenges, such as high cost, strict technical requirements, and post-processing requirements. In addition, metal 3D printed parts still need long-term verification in terms of mechanical properties and durability.

Future development trends

1. Technological progress: With the continuous advancement of technology, the accuracy and speed of metal 3D printing will be further improved.

2. Material expansion: More metal materials will be developed and applied to 3D printing to meet the needs of different fields.

3. Expansion of application areas: Metal 3D printing will penetrate into more fields, such as construction, shipbuilding, etc.

4. Personalized production: As consumers' demand for personalized products increases, metal 3D printing will play a greater role in customized production.

Metal 3D printing technology has brought revolutionary changes to the manufacturing industry, with a wide range of applications and huge potential. With the continuous advancement of technology and cost reduction, metal 3D printing will play a more important role in the future and promote the sustainable development of the manufacturing industry.

3D printing,Metal 3D printing,SLM,SLA printing,Prototype printing,3D prototyping,3D Printing Services

preceding page

preceding page

Related News

2024-04-05