What are the processing technologies for 3D printing?

Release time:

2025-04-03 18:07

3D printing, as a rapid prototyping technology, has achieved great development and wide application in the past few decades. Its processing technology is the core part of 3D printing technology, which determines the accuracy, efficiency and material use of the printed object. At present, there are many different 3D printing processing technologies on the market. The following are the main ones:

1. Powder sintering process:

The powder sintering process mainly uses high-energy laser or electron beam to locally heat the powdered material to melt and combine with each other, and stack layers to form a solid. This process is suitable for printing materials such as metals and ceramics. Its advantage is that it can produce complex internal structures and has high mechanical properties. However, due to the high cost of equipment, this process is mainly used in high-end manufacturing, aerospace and other fields.

2. Fused Deposition Modeling (FDM):

FDM process is one of the most common 3D printing processes on the market. It heats and extrude plastic filament materials to deposit them layer by layer, and finally cools and solidifies to form a solid. This process is suitable for printing a variety of plastic materials and has the advantages of low cost and simple operation. However, the accuracy of FDM printing is relatively low, and it is mainly used in the prototype manufacturing of civilian consumer products.

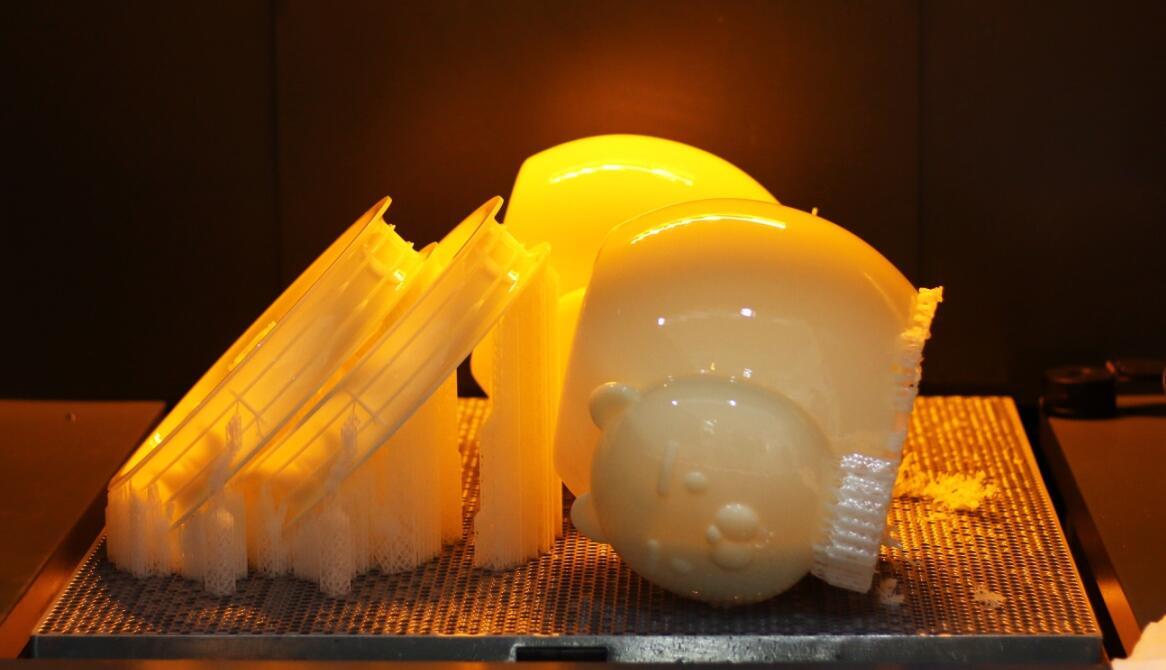

3. Photocuring process (SLA/DLP):

The photocuring process uses ultraviolet laser or LED light source to locally irradiate photosensitive resin to solidify it into layers. This process can produce high-precision, high-resolution models, which are suitable for precision casting, jewelry design and other fields. DLP (digital light processing) is a variant of SLA, which projects a two-dimensional pattern on the surface of liquid resin through a digital projector to achieve rapid curing.

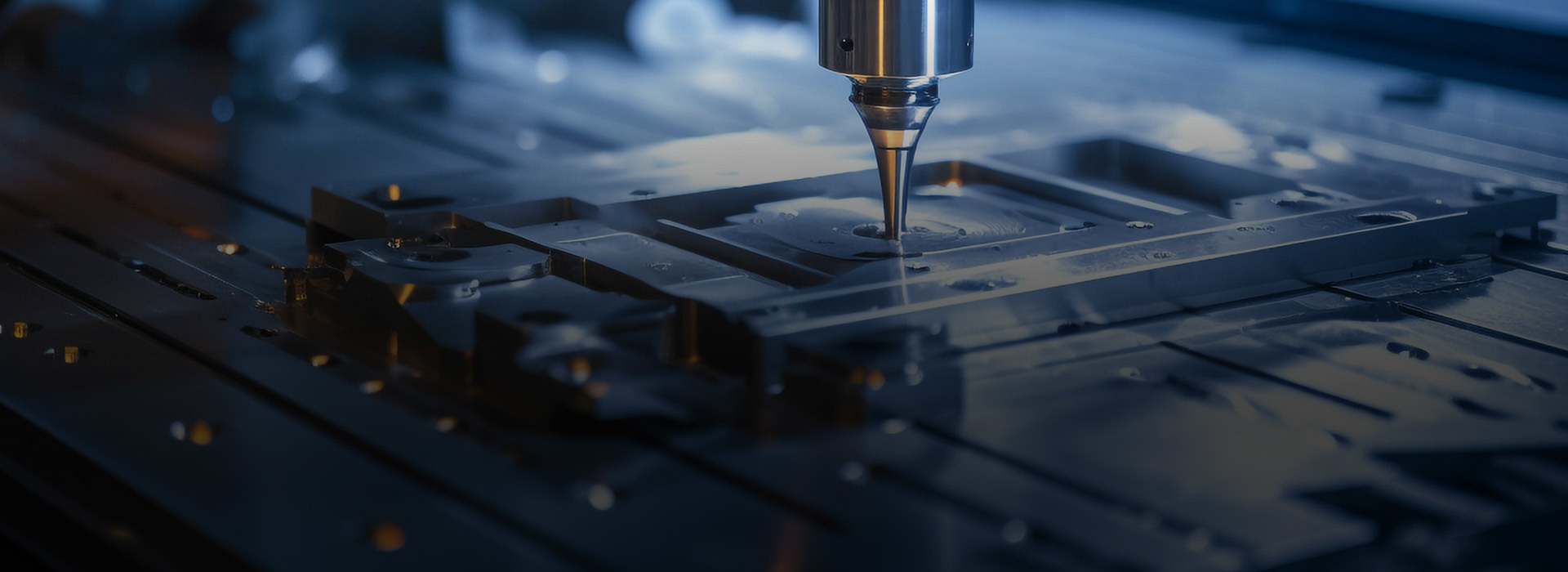

4. Inkjet printing process:

The inkjet printing process sprays the material in the form of droplets onto the building platform through a nozzle, and accumulates layer by layer to form a solid. This process can be applied to the printing of a variety of materials, including metal powder, ceramic slurry, etc. The inkjet printing process has the characteristics of high precision and high efficiency, and is suitable for manufacturing parts and components with complex details.

5. Stereo Lithography:

Stereo lithography is a process based on photosensitive polymers that creates three-dimensional structures in photosensitive resins through computer-controlled light sources. This process can produce high-quality, high-precision models, which are widely used in industrial design, artistic creation and other fields.

6. Material Jetting:

The material jetting process sprays a binder onto a powdered material through a nozzle to bond the material into shape. This process can print a variety of materials, including metals, ceramics, etc., and can produce parts with complex internal structures. The material jetting process is highly flexible and customizable, and is suitable for manufacturing personalized products and small batch production.

In addition to the above main processes, there are also some emerging processes that are constantly developing, such as bioprinting and nanoprinting. These emerging processes have brought broader application prospects for 3D printing technology.

GD prototyping 3D printing technology center has significant manufacturing capabilities, with SLA, SLS, MJF and DLMS printing services, from Plastic to Metal with flexible design. It can realize mass customization, design freedom, reduce assembly process, and can be used as a low-cost production process.

In general, different 3D printing processing technologies have different characteristics and advantages, and are suitable for different application fields. Choosing a suitable process depends on factors such as the material of the printing object, precision requirements, and production efficiency. With the continuous development of technology, 3D printing processes will become more diversified, efficient, and intelligent in the future, bringing greater changes and development to the manufacturing industry.

3D printing,Prototype printing,Metal printing

preceding page

preceding page

Related News

2024-04-05