Why choose five-axis machining for automobile engine parts?

Release time:

2025-03-27 18:28

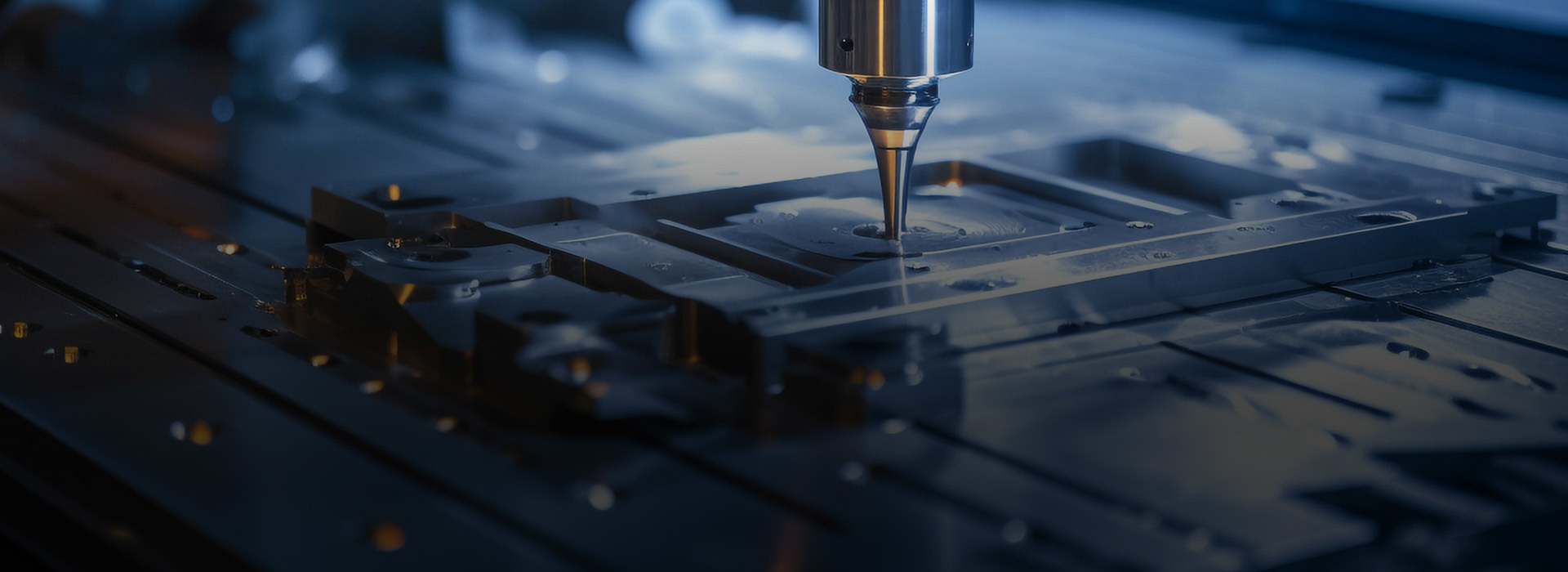

With the rapid development of the automobile industry, the improvement of engine performance has put higher and higher requirements on the processing accuracy and efficiency of parts. Five-axis machining, as an advanced CNC machining technology, is widely used in the production and manufacturing of automobile engine parts. Tina from GD prototyping discusses why automobile engine parts choose five-axis machining from multiple perspectives.

Overview of five-axis machining technology

Five-axis machining refers to the machine tool with five motion axes, which can achieve high-precision machining of complex curved surfaces and special-shaped parts. Five-axis machining technology has the following characteristics:

1. High efficiency: Five-axis machining can complete the cutting of multiple machining surfaces simultaneously, improving machining efficiency.

2. High precision: Five-axis machining can achieve sub-micron or even nano-level machining accuracy, meeting the high-precision requirements of engine parts.

3. Good flexibility: Five-axis machining can adapt to the machining of parts of various complex shapes, especially for the machining of curved surfaces and special-shaped parts of automobile engines.

2. Characteristics of automobile engine parts

Automobile engine parts have the following characteristics:

1. High precision: Engine parts require high-precision machining to ensure the stability and reliability of engine performance.

2. High material requirements: Engine parts usually use high-strength, high-temperature performance materials, such as aluminum alloy, cast iron, etc.

3. Complex structure: The structure of engine parts is complex, especially the intake and exhaust system, cylinder block, etc., which requires a large number of curved surfaces and special-shaped parts processing.

Reasons for choosing five-axis machining for automobile engine parts

1. High-precision machining requirements: Automobile engine parts require high-precision machining, and five-axis machining technology can meet the submicron or even nanometer machining accuracy requirements to ensure the stability and reliability of engine performance.

2. Advantages of complex surface machining: Five-axis machining technology is suitable for machining parts of various complex shapes, especially the machining of curved surfaces and special-shaped parts of automobile engines, which can greatly improve machining quality and efficiency.

3. Improve production efficiency: Five-axis machining can complete the cutting of multiple machining surfaces simultaneously, which can significantly improve production efficiency and reduce production costs compared with traditional machining methods.

4. Wide material adaptability: Five-axis machining technology is suitable for a variety of materials, such as aluminum alloy, cast iron, etc., which can meet the material requirements of automobile engine parts.

5. Customized production needs: There are many types of automobile engine parts. The flexibility and high precision of five-axis machining enable it to adapt to customized production needs and meet the needs of different models.

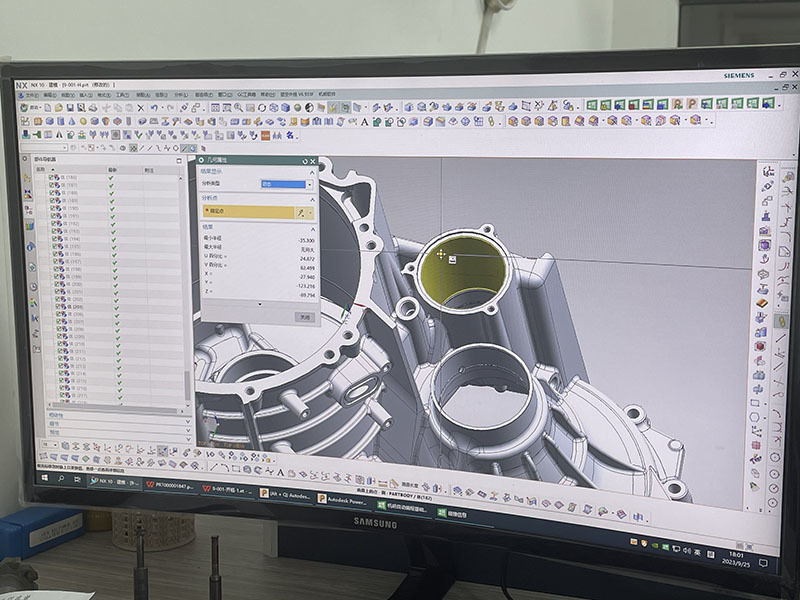

Case analysis

Take the automobile engine cylinder block as an example. The cylinder block is one of the core components of the engine, with complex structure, high precision, and strict material requirements. The application of five-axis machining technology in cylinder block machining can achieve submicron machining accuracy and ensure the sealing and performance stability of the cylinder block. At the same time, five-axis machining can complete the cutting of multiple surfaces at one time, improve production efficiency, and reduce production costs.

GD prototyping Simultaneous 5-axis CNC milling is an advanced processing technique that can manufacture high-precision and complex part. The reasons for choosing five-axis machining for automobile engine parts mainly include high-precision machining requirements, complex surface machining advantages, improved production efficiency, wide material adaptability, and customized production requirements. With the continuous development of the automobile industry, five-axis machining technology will play an increasingly important role in the manufacturing of automobile engine parts.

engine machining,Five-axis machining,engines cnc machining

preceding page

next page

preceding page

next page

Related News

2024-04-05