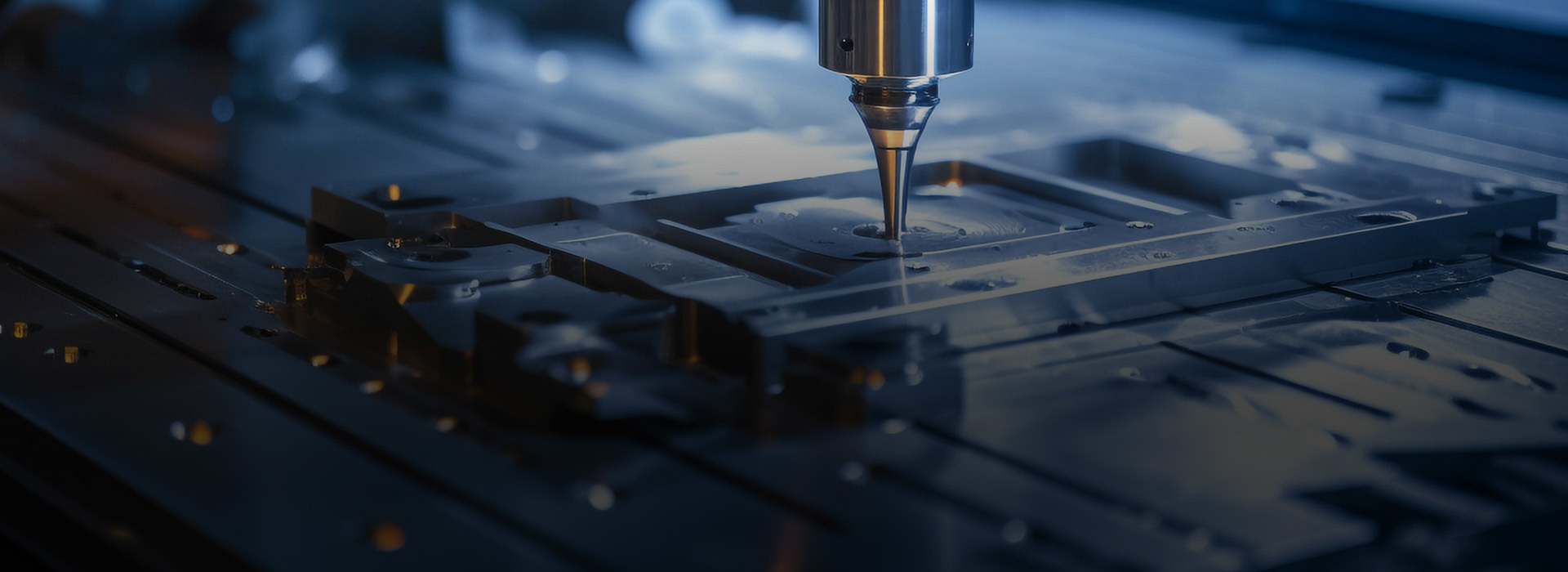

How to process brass parts with CNC

Release time:

2025-03-27 11:01

Brass is a common material for CNC machining due to its good cutting performance and mechanical properties

Brass classification and characteristics

Ordinary brass: good plasticity, high strength, excellent cutting performance, but there is a risk of cracking

Aluminum brass: high strength, best corrosion resistance, better processing performance in hot state

Iron brass: high hardness, good cutting performance, but hot processing is required to avoid corrosion and cracking

Brass CNC machining process

1. Programming and path optimization

Use CAD/CAM software to generate G code and optimize tool paths to reduce empty passes and machining time

Avoid cutting from the end points of the workpiece, and give priority to cutting from the midpoint to reduce burrs

2. Clamping and positioning

The workpiece needs to be fixed by a fixture to ensure accurate centering (such as four-side centering and top surface as zero point)

3. Machining execution

Rough machining: quickly remove the allowance and pay attention to smooth chip removal38. Finishing: Use small step distance and high speed to ensure dimensional accuracy and surface finish

Cooling and quality control of brass CNC processing

Coolant use

Brass processing usually does not require coolant, but copper needs to use coolant that does not contain sulfur, phosphorus, or chlorine

Quality inspection

After processing, use calipers and micrometers to check dimensional tolerances to ensure that they meet design requirements

Post-processing

Remove burrs (manual or vibration polishing), and perform surface treatment (such as passivation, electroplating, chemical polishing) when necessary

Brass CNC processing can efficiently complete the precision processing of brass parts through the above process and parameter optimization, while taking into account quality and cost control.

Brass CNC machining,Brass CNC,CNC Brass,Brass Parts CNC machining

preceding page

next page

preceding page

next page

Related News

2024-04-05