Impeller five-axis CNC machining process

Release time:

2025-03-05 17:22

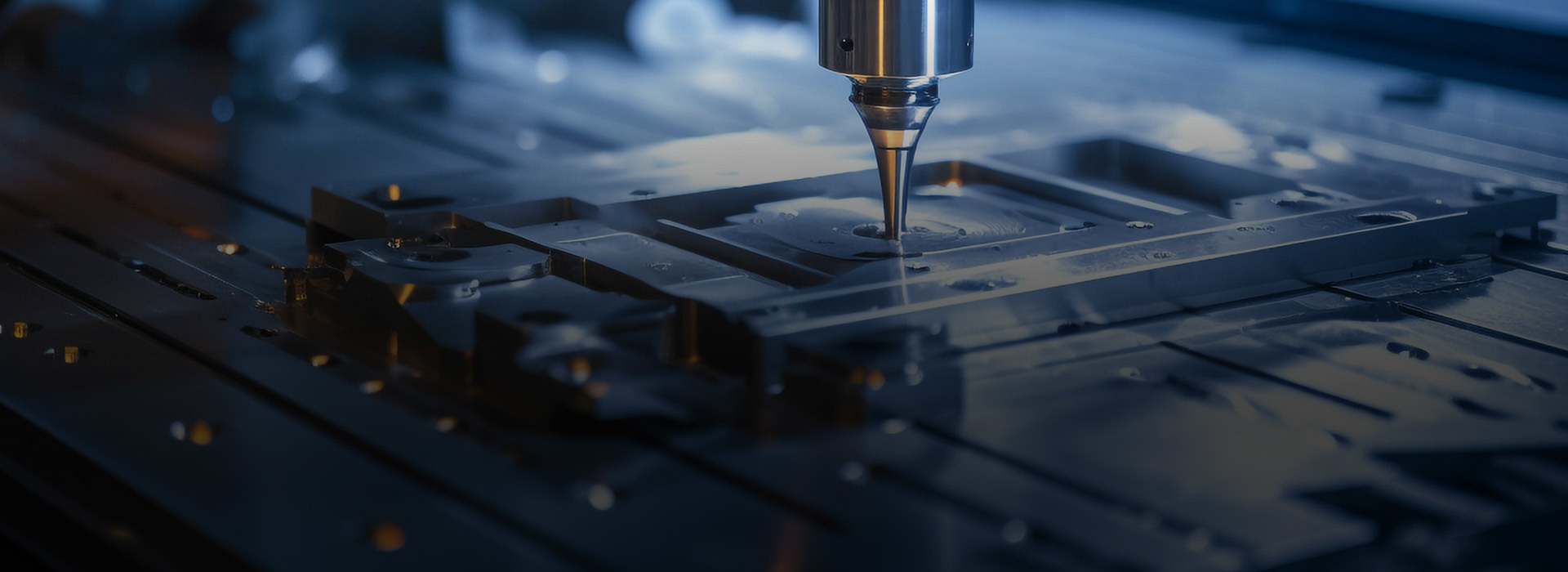

As an important mechanical component, impellers are widely used in energy, aviation, chemical industry and other fields. With the continuous advancement of science and technology, five-axis CNC machining technology has been widely used in impeller manufacturing. This article will introduce in detail the technology, process and precautions of impeller five-axis CNC machining.

Impeller five-axis CNC machining technology

1. Overview of five-axis CNC machining

Five-axis CNC machining refers to the process of machining impellers using five-axis linkage CNC machine tools. Five-axis machine tools can achieve precise machining of complex spatial curves and are suitable for parts with complex curved surfaces such as impellers.

2. Features of impeller five-axis machining technology

(1) High precision: Five-axis CNC machining can achieve sub-millimeter or even micron-level machining accuracy, meeting the high-precision requirements of impellers.

(2) High efficiency: Five-axis linkage machining can complete multiple processes of impellers at one time, improving machining efficiency.

(3) High adaptability: It is suitable for machining of various materials and impeller shapes and has a wide range of applications.

Impeller five-axis CNC machining process

1. Preliminary preparation

(1) Design the impeller model: Perform three-dimensional modeling according to requirements and determine the size, shape and other parameters of the impeller.

(2) Select the appropriate tool: Select the appropriate tool according to the impeller material and processing requirements.

(3) Prepare process documents: Develop a detailed machining process, including machining paths, parameter settings, etc.

2. Machining process

(1) Blade rough machining: Remove the excess to prepare for subsequent fine machining.

(2) Blade fine machining: Achieve the accuracy and surface quality required by the design.

(3) Hub machining: Complete the machining of the hub part to ensure the matching accuracy with the blade.

3. Post-processing

(1) Inspection and correction: Perform quality inspection on the finished impeller and correct the unqualified parts.

(2) Surface treatment: Perform surface treatment such as spraying and polishing according to requirements.

Precautions for impeller five-axis CNC machining

1. Safe operation: Strictly abide by the machine tool operating procedures to ensure personal safety.

2. Tool selection and replacement: Choose tools reasonably, replace tools with severe wear in time, and avoid accidents such as tool breakage.

3. Processing parameter setting: Set processing parameters reasonably according to factors such as impeller material and tool type to ensure processing quality.

4. Quality control: Strictly control the quality of each link to ensure that the performance of the final product meets the requirements.

5. Environmental protection: Reasonably handle processing waste to reduce the impact on the environment.

Impeller five-axis CNC machining is an efficient and precise machining method suitable for machining of various materials and impeller shapes. In practical applications, it is necessary to strictly abide by the operating procedures, pay attention to safety and quality control, to ensure the performance and quality of the impeller. With the continuous development of science and technology, five-axis CNC machining technology will play a more important role in the field of impeller manufacturing.

cnc machining,five-axis CNC machining,Impeller five-axis CNC machining,Impeller machining

preceding page

next page

preceding page

next page

Related News

2024-04-05