Precision Aluminum 5-Axis CNC Machining: Elevating Manufacturing Quality and Efficiency

Release time:

2025-12-24 17:41

Precision Aluminum 5-Axis CNC Machining: Elevating Manufacturing Quality and Efficiency

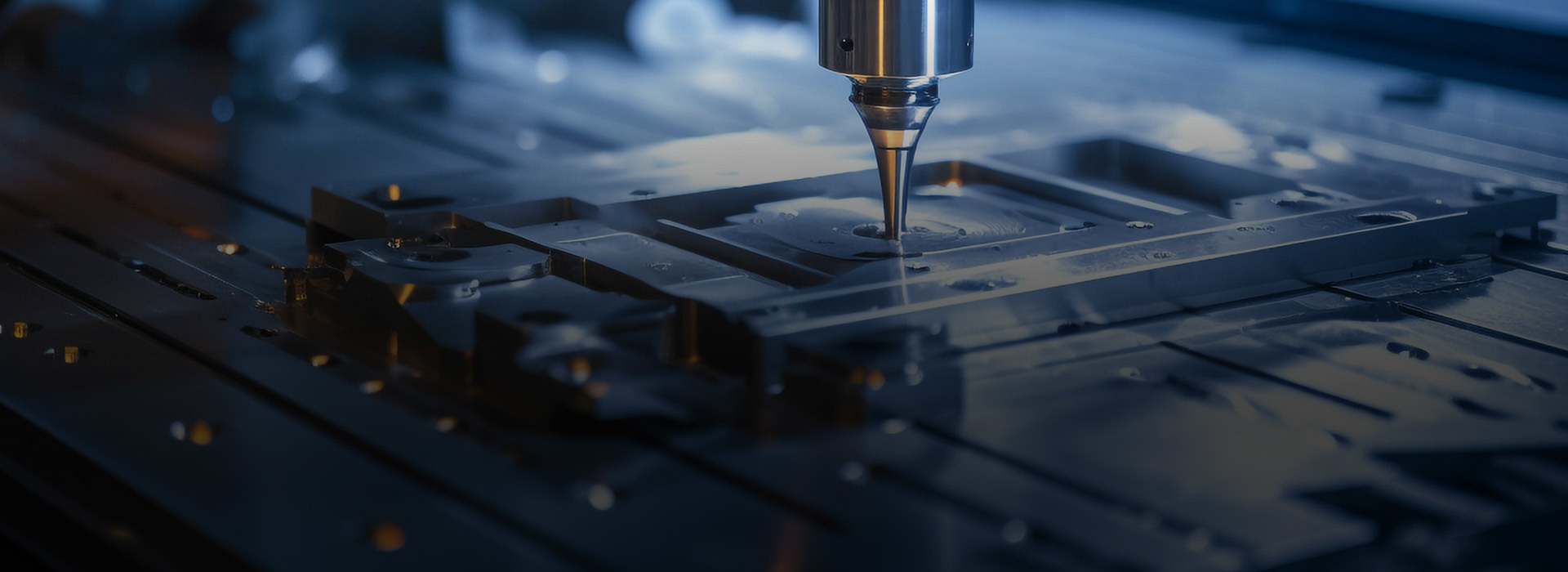

In the fast-paced world of modern manufacturing, precision machining technology is the driving force behind product innovation and enhanced production capabilities. Among the most powerful tools for achieving high-quality results is Aluminum 5-Axis CNC Machining. With its superior accuracy, flexibility, and efficiency, this advanced machining method is the go-to solution for industries such as aerospace, automotive, and robotics, where high-performance parts are essential.

The Advantages of Aluminum 5-Axis CNC Machining

1. Unmatched Precision for Complex Designs

Aluminum is widely used in high-performance industries due to its light weight, corrosion resistance, and strength. 5-axis CNC machining is the ideal solution for processing aluminum into intricate, high-precision components. Unlike traditional 3-axis machining, 5-axis CNC allows for cutting, drilling, and shaping from multiple angles, achieving superior dimensional accuracy and complex geometries with micro-level precision. Even parts with multi-curved surfaces, deep cavities, and complex holes are easily produced, ensuring your designs meet the most demanding standards.

2. Increased Production Efficiency and Lower Costs

One of the most significant benefits of aluminum 5-axis CNC machining is its ability to reduce lead times and enhance overall efficiency. The ability to machine parts in a single setup minimizes the need for multiple operations, reducing handling times and errors. This results in faster production, which not only shortens the time-to-market but also helps reduce labor and tooling costs. Whether you’re producing prototypes or full production runs, the efficiency of 5-axis machining allows you to deliver more, faster, and with greater consistency.

3. Customization for Diverse Needs

Every industry has unique requirements, and aluminum 5-axis CNC machining offers unparalleled versatility to cater to diverse customer demands. From prototype development to mass production, this process can be tailored to produce components with varying degrees of complexity, size, and material specifications. Whether your business needs highly customized parts for a single project or large-scale production for an ongoing demand, aluminum CNC machining provides the flexibility to meet both small and large orders efficiently.

4. Superior Surface Finish for High-Quality Parts

In precision manufacturing, the surface finish is often just as important as the structural integrity of the part. 5-axis CNC machining not only delivers exceptional accuracy in shape but also ensures smooth, high-quality finishes on aluminum components. With post-processing options such as anodizing, polishing, and sandblasting, we can enhance the appearance and durability of each part, making it both functional and visually appealing.

Applications of Aluminum 5-Axis CNC Machining Across Industries

Aerospace Industry

In the aerospace industry, precision is critical. Aluminum parts used in aircraft engines, wing structures, and support components must meet stringent performance and safety standards. 5-axis CNC machining allows manufacturers to produce high-precision aerospace parts that not only perform optimally but are also lightweight, contributing to better fuel efficiency and performance.

Automotive Manufacturing

With increasing demand for lightweight, high-performance vehicles, aluminum is becoming a primary material in automotive manufacturing. 5-axis CNC machining plays a vital role in producing complex engine components, chassis parts, and interior structures, ensuring that each component meets the high standards required for performance, safety, and design.

Robotics and Automation

In robotics and automation, precision and reliability are paramount. Whether it's for robotic arms, gears, or structural components, aluminum 5-axis CNC machining enables the production of highly intricate parts with excellent strength-to-weight ratios, enhancing the overall performance and longevity of robotic systems and automated equipment.

Why Choose Aluminum 5-Axis CNC Machining?

-

Cutting-Edge Technology, Reliable Quality

We employ the latest 5-axis CNC machining equipment and techniques to ensure every part we produce meets the highest standards of quality and precision. Our machines are capable of processing aluminum and other high-strength materials with micron-level accuracy. -

Precision Engineering, Tailored to Your Needs

Whether you're developing a one-off prototype or producing thousands of parts for mass production, we offer flexible solutions that are tailored to your exact specifications. Our team of experienced engineers works closely with you to ensure that every project is completed to your satisfaction. -

Fast Turnaround, Reliable Delivery

At our facility, we understand the importance of time in manufacturing. That’s why we prioritize fast turnaround times without compromising on quality. We offer flexible delivery options to meet your deadlines, ensuring that your products reach you on time, every time. -

Global Reach, Industry Expertise

Our aluminum 5-axis CNC machining services are trusted by clients across the globe, from startups to established enterprises. With years of expertise and a proven track record, we are well-positioned to serve industries such as aerospace, automotive, robotics, and more. -

Conclusion: The Future of Precision Manufacturing

Aluminum 5-axis CNC machining is revolutionizing the way industries produce high-performance components. With its ability to deliver exceptional precision, faster production times, and high-quality finishes, it's no wonder that this technology is rapidly becoming the gold standard in manufacturing. Whether you're in aerospace, automotive, or robotics, our aluminum CNC machining services can help you achieve the precise, durable, and lightweight parts you need to stay competitive.

Choose aluminum 5-axis CNC machining and experience the future of precision manufacturing today. Our team is ready to provide you with the highest-quality products and services, ensuring your projects are completed to the most exacting standards.

5AxisCNC,AluminumMachining,PrecisionManufacturing,CNCParts,CustomMachining

preceding page

Related News

2024-04-05