ENERGY INDUSTRY

Energy leads us to explore future

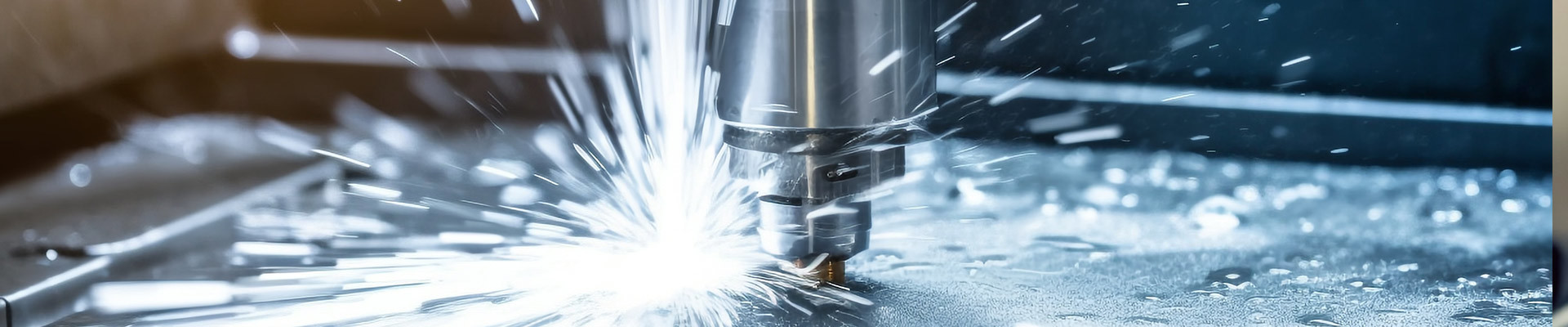

GD prototyping has participated lots of engery projects over past years, such as mining, oil, military,gas and nuclear fields. Our high quality and precision machining services allows us to provide defect-free precision manufacturing.

We regularly conduct internal audits, evaluating and upgrading processes and tooling to ensure all your parts are of the highest quality, as well as cost-effective.

Energy Industry Manufacturing Capabilities

The application of GD prototyping CNC processing in the energy industry is mainly reflected in the manufacturing of high-precision parts, complex structure processing and special material processing.

CNC machining is used to manufacture fan blade molds to ensure that the blade aerodynamic shape meets the design requirements. At the same time, key drive components such as gears, gearbox housings, main shafts, generator frames, etc. are produced. The flatness error can be controlled within 0.02mm/m to ensure the reliability and stability of fan operation.

Aerospace Industry Experience In

Magnetic Separator Components

Picture Display