ELECTRONIC APPLIANCES

Building Better Models for Our Life

Electronic devices of every kind are integrated into our daily lives. Their functions vary but they all depend on packaging and enclosure solutions that are lightweight, durable, convenient to use and with designs that can be quickly transitioned from prototypes to volume production in response to rapidly changing market conditions.

The design and manufacture of electromechanical products is becoming significantly more complex, requiring more intricate components, shorter lead times, higher investments and risks. Complex assembly uses integrated components, both fabricated and commercial, to a level of integration just short of a turnkey system and more integrated than an electro-mechanical assembly.

With GD prototyping's cost-efficient contract manufacturing capabilities, you can be confident your diverse designs, fluctuating demand and short-term delivery schedules will be accommodated.

Case - Coffee Machine

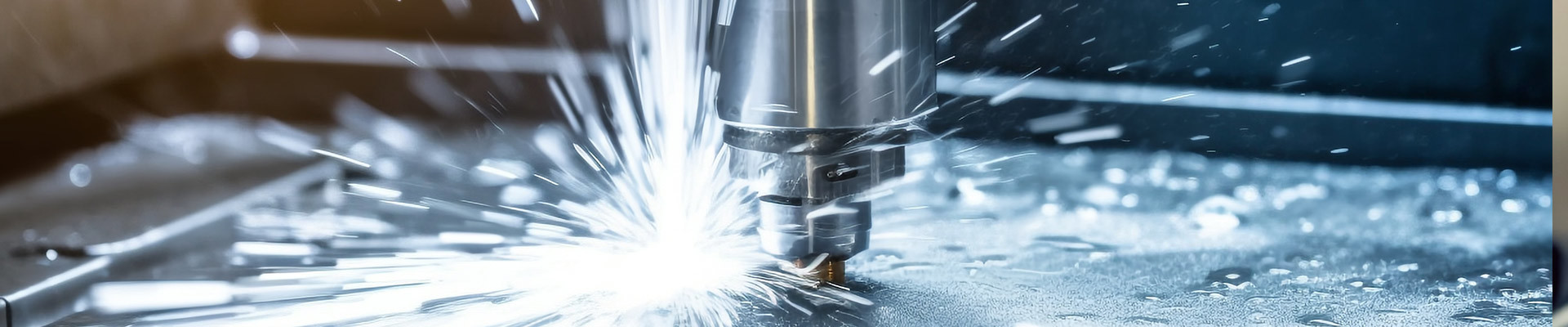

According to the different parts' 3D drawing, generally use plastic(for housing) and metal materials to process by CNC, then apply finishing like Burnshing, Silk Screen, Spray Painting and so on in accordance with products' characteristics, structure and use group.

The housing is the most conspicuous part in all the Electronic Appliances, and now the market requirement is more and more strict, because the first element to attract end consumers is whether or not the product appearance is enough to catch the eye. Besides there is a lot of elements need to be considered, and the prototype can be well applied in these goods. Prototype can enable the design or manufacturer find out these problems timely and reduce the huge loss cause by blind mass production.

Aerospace Industry Experience In

undefined

Picture Display