Description

Advantages of CNC Machining

High Machining Precision

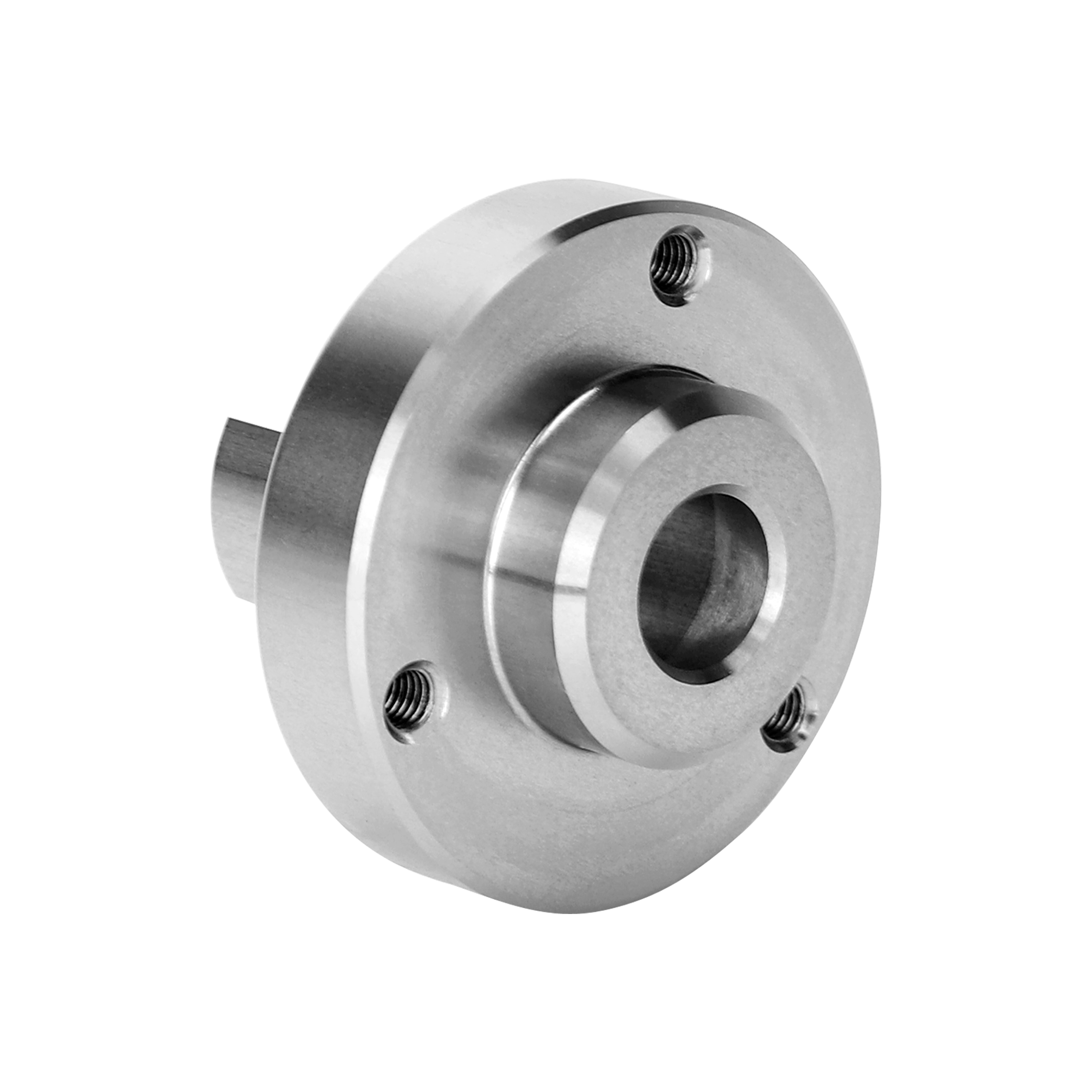

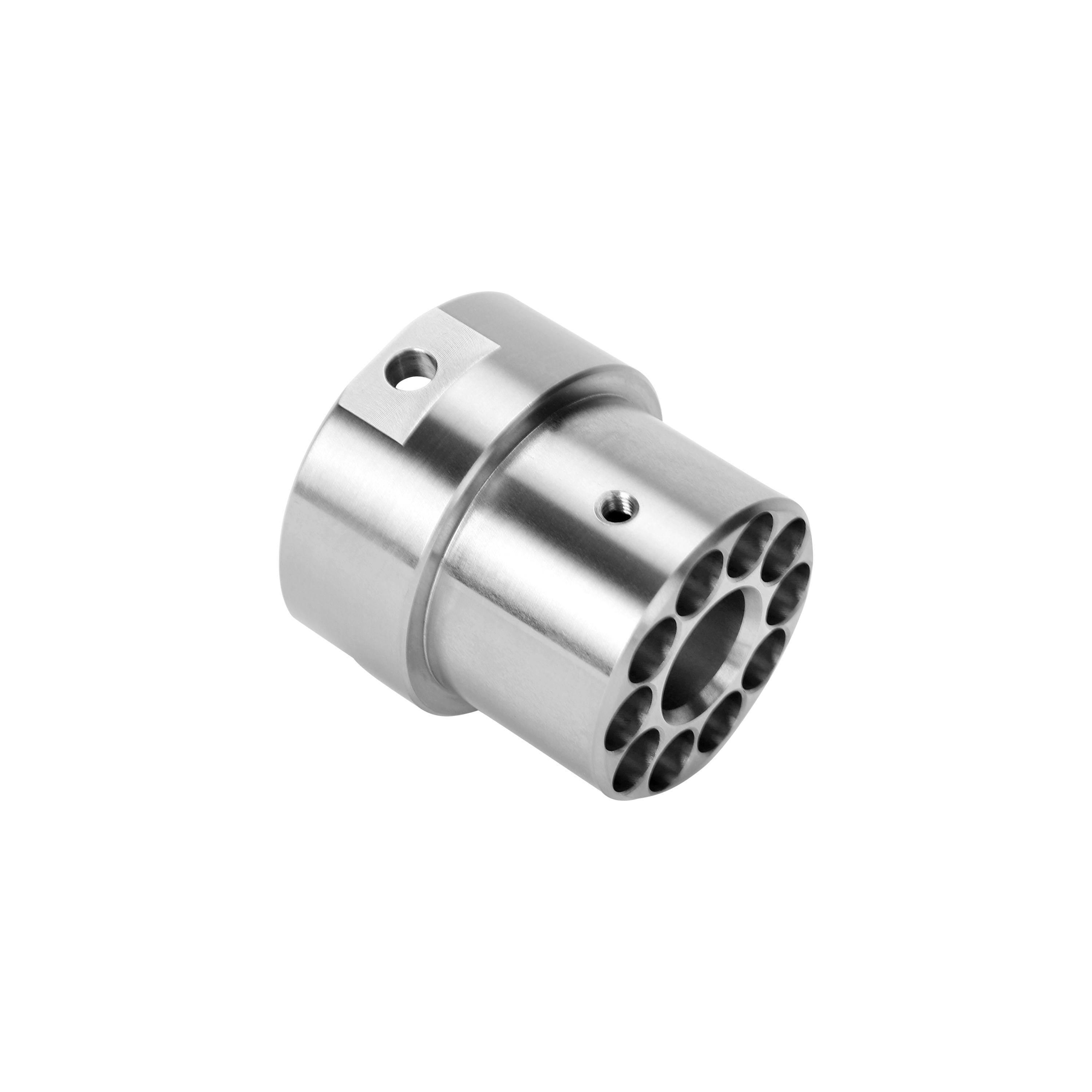

CNC machining enables micron-level control, ensuring dimensional accuracy for external diameters, internal holes, grooves, and other components.

This is particularly suitable for components with step, hole, and groove combinations, avoiding cumulative errors.

Excellent Surface Quality

Smooth CNC machining tool paths and low surface roughness.

Parts can achieve a high finish directly, reducing the need for subsequent polishing.

Complex Structures Can Be Completed in a Single Clamping

External diameters, internal holes, grooves, and end faces can be completed in a single clamping.

Reduced inter-process errors improve coaxiality and fit accuracy.

High Machining Efficiency

High-speed cutting is possible, resulting in higher continuous machining efficiency than conventional lathes.

Excellent stability and consistent machining during mass production.

High Flexibility

Process parameters can be quickly modified through programming, accommodating small-batch production of multiple products.

Design changes eliminate the need for specialized fixtures, reducing production setup time.

High Level of Automation

Unmanned machining is possible, reducing manual intervention.

Suitable for continuous production, reducing labor costs.

Widely adaptable

It can process materials such as steel, aluminum, copper, and engineering plastics.

It is particularly suitable for mechanical parts requiring precise steps, holes, and sealing grooves.

preceding page

next page

信息为测试元素,使用时候可删除该元素放置自己想放的元素

页签③

富文本内容绑定数据后可解析HTML语言内容

信息为测试元素,使用时候可删除该元素放置自己想放的元素

页签④

富文本内容绑定数据后可解析HTML语言内容

信息为测试元素,使用时候可删除该元素放置自己想放的元素

Related Products

Online Message

If you are interested in cooperation, please contact us immediately and we will give you feedback as soon as possible!