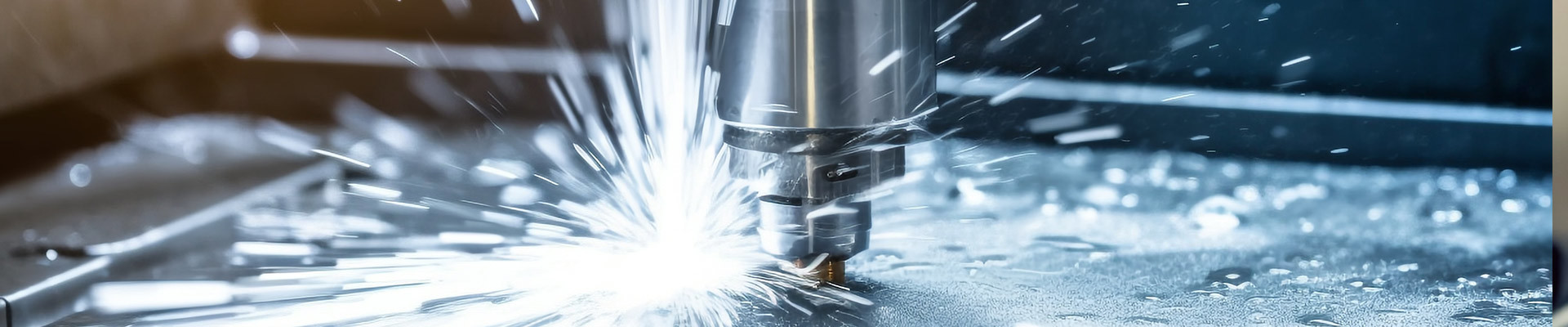

Aluminum alloy parts machining

Precision machined aluminum alloy metal parts are parts of some kind of machinery or equipment with complex hole positions and surface finish. Such parts are usually used in equipment with high precision requirements, such as aviation, automobile, machinery or electronics fields.

Classification:

Keywords:

parts cnc machining

cnc machining

cnc metal machining

Aluminum alloy machining

Description

Precision machined aluminum alloy metal parts are parts of some kind of machinery or equipment with complex hole positions and surface finish. Such parts are usually used in equipment with high precision requirements, such as aviation, automobile, machinery or electronics fields.

The advantages of using CNC (computer numerical control) for this part are mainly reflected in the following aspects:

High precision and consistency: CNC machining can achieve extremely high machining accuracy by controlling the machine through computer programs. For parts with multiple complex holes and delicate surface treatment requirements, CNC machining can ensure that the size and shape of each part are consistent, avoiding errors in manual processing.

Complex shape processing: The part shown in the figure has many irregular holes and delicate surface details. CNC machining is very suitable for the manufacture of these complex geometric shapes. Traditional machining methods are difficult to achieve such high precision and complex shapes.

High efficiency: CNC machine tools can run continuously and perform automated processing without manual intervention, reducing production cycles and improving production efficiency. This is especially important for parts that are produced in large quantities or require frequent design changes.

High material utilization: CNC machining can maximize the use of raw materials and reduce waste. By accurately controlling the cutting path and cutting amount, material loss can be effectively reduced.

Automation and reduced manual operation: The CNC machining process can be fully automated, reducing the need for manual operation and reducing the risk of manual errors. In addition, the operator of CNC machining only needs to program and set up, and the subsequent machining process does not require too much intervention.

Multifunctional machining: CNC machine tools can not only perform milling, drilling, turning and other machining methods, but also complete multiple processes on the same equipment, reducing the number of workpiece clamping times and ensuring machining accuracy and efficiency.

Low machining difficulty and cost optimization: Although the initial equipment investment for CNC machining is high, the unit cost can be greatly reduced as the production batch increases. At the same time, the high precision and stability of CNC machine tools can avoid rework and scrap caused by errors in the production process, thereby reducing production costs.

Flexibility and customizability: By changing the program of the CNC machine tool, the design or production process of the part can be quickly adjusted, which is very suitable for production needs that require multiple adjustments or customization.

信息为测试元素,使用时候可删除该元素放置自己想放的元素

页签③

富文本内容绑定数据后可解析HTML语言内容

信息为测试元素,使用时候可删除该元素放置自己想放的元素

页签④

富文本内容绑定数据后可解析HTML语言内容

信息为测试元素,使用时候可删除该元素放置自己想放的元素

Related Products

Online Message

If you are interested in cooperation, please contact us immediately and we will give you feedback as soon as possible!