Precision 5-Axis CNC Machining for Complex Impellers

Release time:

2025-10-14 17:55

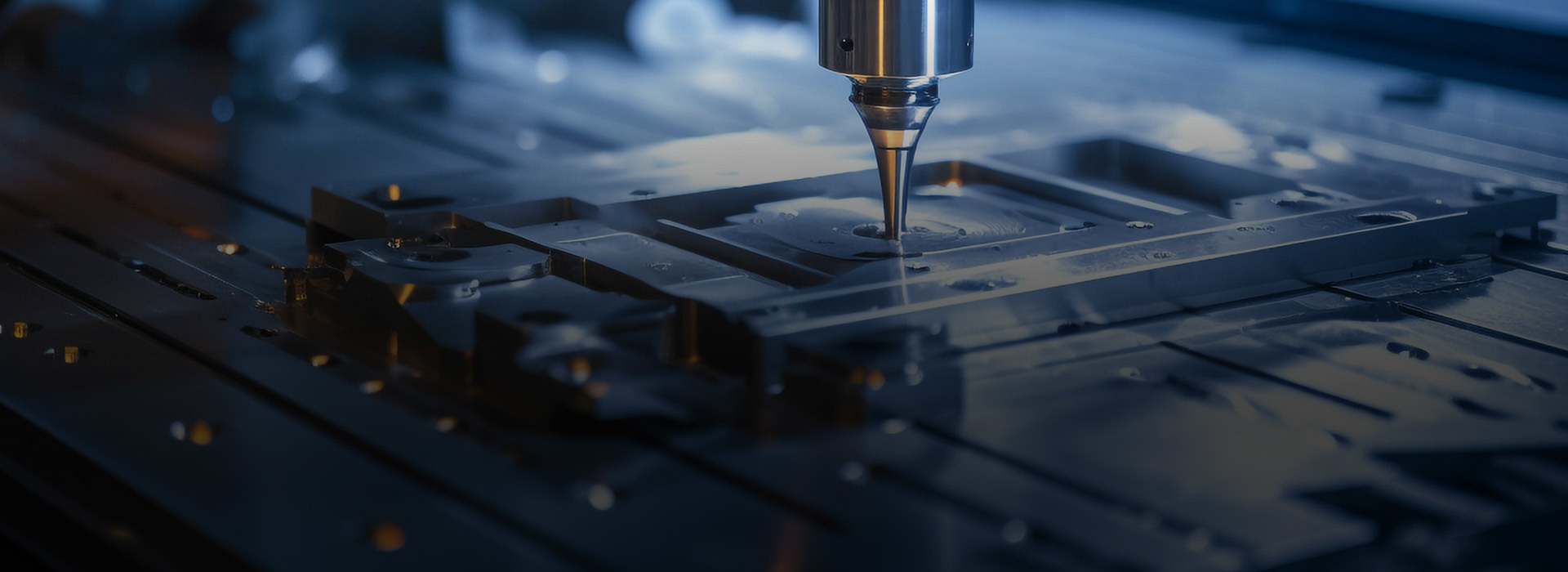

This precision-machined aluminum impeller is crafted through 5-axis CNC machining, allowing complex geometries to be produced in a single setup — ensuring exceptional accuracy,

In high-demand industries such as aerospace, energy, and turbo machinery, impellers are far more than mechanical components — they are the core of fluid dynamics, directly influencing efficiency, stability, and lifespan of an entire system.

At GD prototyping , we specialize in high-precision 5-axis CNC machining to produce impellers that meet the world’s toughest performance requirements.

Complex Geometry, Absolute Precision

Modern impeller designs feature twisted blades, tight clearances, and freeform surfaces that challenge conventional 3-axis machining.

Our advanced 5-axis machining centers allow simultaneous multi-directional movement, enabling complete machining in a single setup.

This eliminates repositioning errors, shortens production cycles, and ensures dimensional accuracy within ±0.005 mm across all critical areas.

Optimized Surface Integrity

A smooth surface finish is vital to reduce flow loss and improve aerodynamic or hydrodynamic efficiency.

Through adaptive toolpath optimization and high-speed cutting strategies, we achieve a mirror-like surface finish (Ra < 0.4 μm), minimizing post-processing and enhancing the performance of each impeller under high rotational speeds.

Material Expertise

We work with a wide range of high-performance materials —

including aluminum alloys, stainless steels, Inconel, and titanium — each selected to meet specific operational conditions such as high temperature, corrosion, and fatigue resistance.

Our toolpaths and cutting parameters are fine-tuned for each material to guarantee both mechanical strength and microstructural integrity.

Quality Assurance from Design to Delivery

From CAD/CAM programming to on-machine probing and CMM inspection, every stage of production is guided by a strict quality control process.

Each impeller is 100% verified for geometry, balance, and dimensional tolerance before shipment, ensuring consistent, repeatable precision across production batches.

Applications

Turbochargers & Compressors

Aerospace Turbomachinery

Industrial Pumps & Blowers

Energy Conversion Systems

Marine Propulsion Equipment

At GD prototyping, precision is not just a specification — it’s our philosophy.

Our goal is to transform your most challenging designs into functional, high-efficiency components that drive performance, reliability, and innovation forward.

5-Axis CNC Machining,Precision 5-Axis CNC Machining,impeller machining,Impeller CNC machining,Turbine CNC machining

Related News

2024-04-05