5-Axis CNC Machining -Turning Complexity into Precision

Release time:

2025-10-13 17:14

In modern manufacturing, accuracy and efficiency define the future.

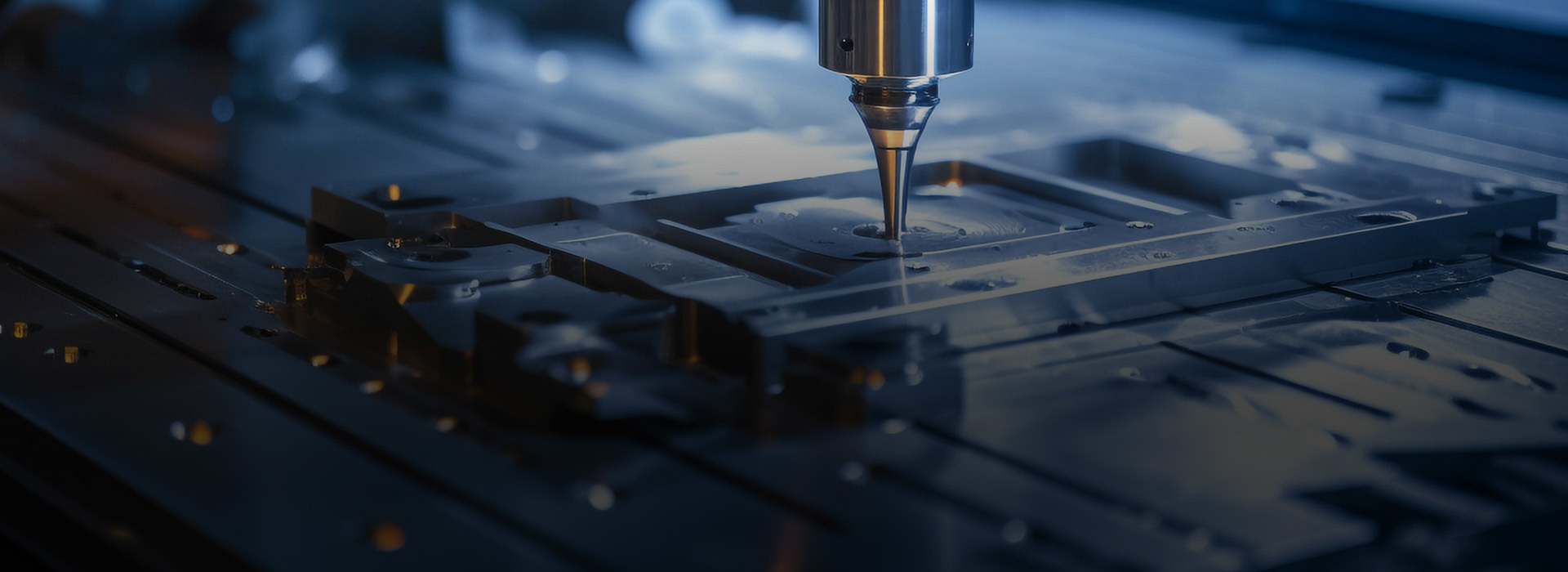

The photo above captures our DMG GMU-400 five-axis machining center in action — transforming solid aluminum into high-precision components with exceptional surface quality and dimensional accuracy.

With advanced 5-axis simultaneous machining, we can complete multiple surfaces in a single setup, ensuring tighter tolerances, faster turnaround, and higher consistency.

Every aluminum part we produce undergoes meticulous process planning and strict quality control.

We understand that each component carries both performance and reliability, so we put precision and craftsmanship into every tool path and every cut.

Our Advantages:

5-axis simultaneous machining for complex geometries and curved surfaces

Tolerance accuracy up to ±0.005 mm

One-stop service: Programming → Machining → Surface Treatment → Inspection

Flexible production for both prototypes and volume orders

From aerospace and medical devices to precision instruments and automotive parts —

we deliver high-performance CNC solutions that meet the most demanding engineering standards.

📩 Contact us today to discover how our 5-axis precision machining can empower your next project.

Five-axis machining,Five-axis CNC machining,Aluminum CNC machining,Precision five-axis machining

preceding page

preceding page

Related News

2024-04-05