Description

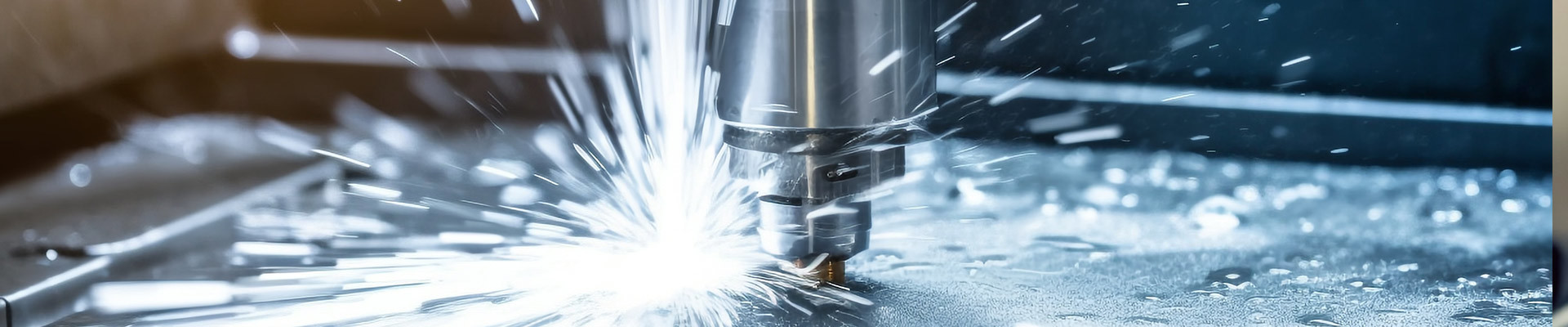

This brass part is manufactured using CNC (Computer Numerical Control) machining technology, ensuring high precision and superior processing results. CNC machining technology enables the creation of complex shapes and high-precision machining requirements, and is widely used in aerospace, automotive, electronics, medical, and other fields.

Process Flow:

Design and Programming: First, 3D design of the part is performed using CAD (Computer-Aided Design) software, and then a CNC machining program is generated using CAM (Computer-Aided Manufacturing) software to ensure the accuracy of the machining process.

Material Preparation: High-quality metal or alloy materials are selected, such as aluminum alloy, stainless steel, copper, or titanium alloy, with material specifications and characteristics determined according to customer requirements.

Rough Machining: Rough machining is performed using a CNC machine tool to remove most of the excess material and form the preliminary shape of the part. This process uses larger tools for efficient cutting.

Finish Machining: In the finish machining stage, smaller, finer tools are used to precisely cut the part, ensuring that the dimensions and surface quality meet the design requirements.

Heat Treatment (if needed): For some materials, heat treatment may be required to improve hardness and strength, ensuring that the part has good mechanical properties during use.

Surface Treatment: Surface treatment is performed as needed, such as spraying, polishing, electroplating, or oxidation, to improve the corrosion resistance, wear resistance, and appearance of the part.

Quality Inspection: High-precision measuring equipment is used to inspect dimensions, appearance, surface roughness, etc., to ensure that the part meets the customer's technical requirements.

Post-processing and Packaging: After machining, post-processing steps such as deburring and cleaning are performed, and then the parts are packaged according to customer requirements to ensure that they are not damaged during transportation.

Advantages:

High Precision: CNC machining offers extremely high machining accuracy, capable of achieving micron-level machining tolerances, meeting stringent engineering requirements.

Complex Shape Machining: Suitable for machining a variety of complex shaped parts, meeting the needs of different fields.

High Efficiency: CNC machining improves production efficiency, suitable for mass production while maintaining high quality.

Flexibility: CNC machine tools can easily adjust parameters to adapt to different design requirements and material types.

Applicable Industries:

Aerospace: Used to manufacture high-precision aerospace parts, such as engine components and airframe structures.

Automotive Manufacturing: Precision parts machining, ensuring part performance and service life.

Medical Equipment: Used to produce high-precision medical instruments and equipment components. Electronics industry: Precision machining of electronic components, such as heat sinks and connectors.

Through CNC machining, we are able to provide customers with high-quality, high-precision parts that meet international standards and satisfy the stringent requirements of various industries.

preceding page

next page

信息为测试元素,使用时候可删除该元素放置自己想放的元素

页签③

富文本内容绑定数据后可解析HTML语言内容

信息为测试元素,使用时候可删除该元素放置自己想放的元素

页签④

富文本内容绑定数据后可解析HTML语言内容

信息为测试元素,使用时候可删除该元素放置自己想放的元素

Related Products

Online Message

If you are interested in cooperation, please contact us immediately and we will give you feedback as soon as possible!