Description

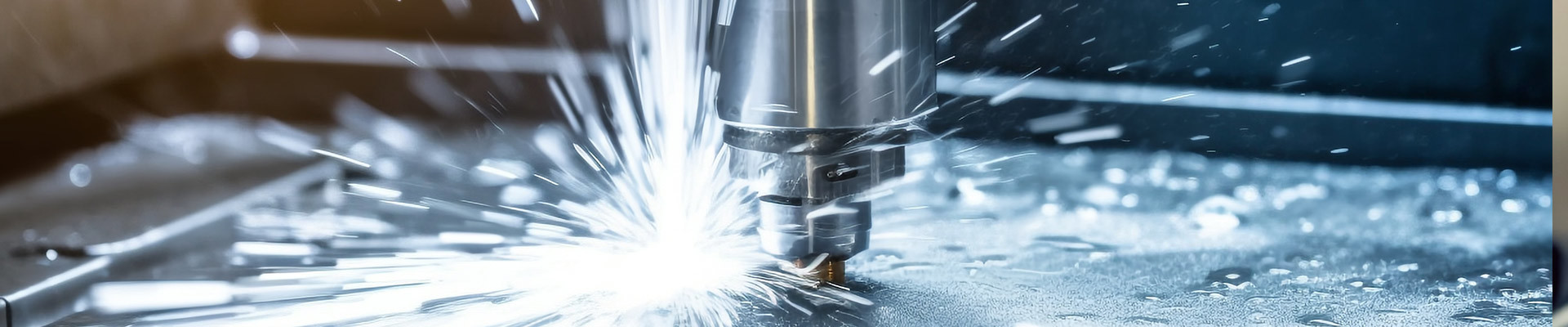

Injection mold technology is a common and important molding process in plastic processing, and is widely used in the fields of automobiles, home appliances, electronics, medical treatment, daily necessities, etc.

The injection molding process is the process of injecting heated molten plastic into the mold cavity and then cooling and solidifying it to obtain the product. This process requires special equipment (injection molding machine) and matching mold (injection mold)

Injection Molding Process

Plastic is heated and melted

The raw material is a thermoplastic (such as ABS, PP, PE, PC, etc.).

The injection molding machine's screw heats and shears the melt into a fluid.

Injection Molding

The molten plastic is injected into the closed mold cavity under high pressure.

Pressure Holding and Cooling

After injection, the pressure holding phase begins to compensate for shrinkage.

The plastic in the mold cools and sets.

Mold Opening and Demolding

The mold opens, and the ejection system ejects the part.

Part Removal

Part removal is performed manually or by a robotic arm.

preceding page

next page

信息为测试元素,使用时候可删除该元素放置自己想放的元素

页签③

富文本内容绑定数据后可解析HTML语言内容

信息为测试元素,使用时候可删除该元素放置自己想放的元素

页签④

富文本内容绑定数据后可解析HTML语言内容

信息为测试元素,使用时候可删除该元素放置自己想放的元素

Related Products

Online Message

If you are interested in cooperation, please contact us immediately and we will give you feedback as soon as possible!