What is Sheet Metal

Sheet metal fabrication relies on a special set of tools across its cutting, welding bending, punching and joining processes to force the metal into the desired shape. Sheet metal fabrication is the most cost-effective choice for metal components with specified wall thickness. Best Prototypes can provide a wide range of sheet metal capabilities, from high quality cutting, punching, bending, to welding services.

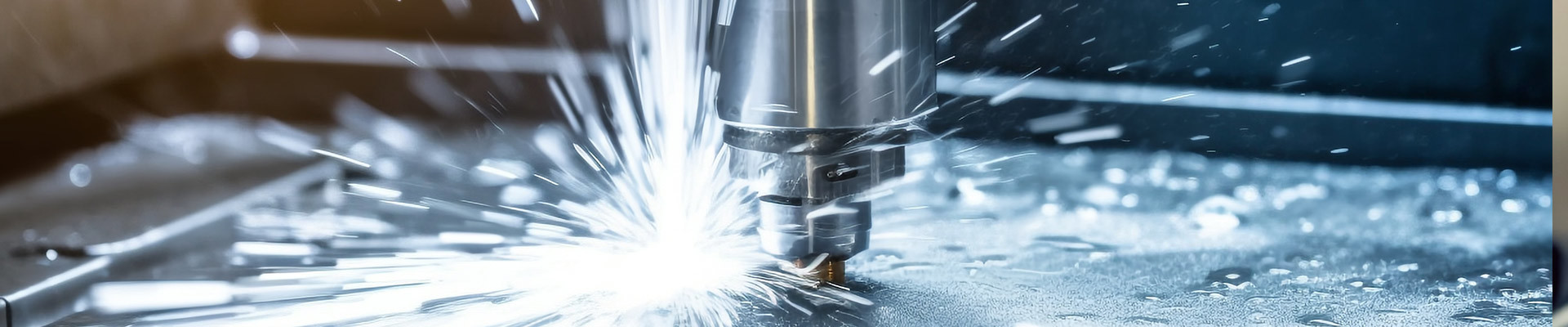

Sheet Metal - Technologies

Laser cutters are CNC machines that use a thin, high-powered laser beam to cut materials.

– Cutting area Up to 4000 x 6000 mm

– Maximum material thickness <20mm

– Laser sources Up to 20 kW

– Repeatability Ps: +/- 0.05 mm

– Positioning accuracy Pa: +/- 0.1 mm

Pushes material through a press into the desired shape, creating either a hole or an indentation.

– Maximum thickness

– Hole capacity Up to 50mm

Highly accurate, versatile, and durable, capable of cutting up to 10” thick with abrasive additive in the high-pressure fluid stream.

– Maximum cutting area Up to 3000 x

6000 mm

– Maximum material thickness Up to

300 mm

Offers the variable material cutting capability of lasers with a significantly lower capital cost.

– Cutting area Up to 4000 x 6000 mm

– Maximum material thickness <50mm

Forms generally uniform-thickness material to a specific shape or angle along a straight axis.

– Metal folding capacity Up to 300 tons

– Maximum bending length Up to 4000 mm

– Maximum thickness Up to 20 mm

Melts the base materials and fuses it together, forming a metallurgical bond that joins the metals together.

Why Sheet Metal with GD prototyping?

Economical Cost

Sheet Metal is one of the most economical processing technique to fabircate your parts with uniform wall thickness.

Rapid Leadtime

We combine our extensive experience with the industry’s latest tools and technologies to deliver high-quality vacuum casting services on short timelines (typically in 7 to 14 days).

Low Volume Production

The capabilities for Sheet Metal is very tremendous from 1 pc to 100,000 pcs. and this is most effective way to fabricate the sheet metal parts.

Complex Geometry

This technique can fabricate the complex structure easily with its diverse processes.

Picture Display

Sheet metal bending and welding

At GD Prototyping We have rich experience in making sheet metal parts, like CNC stamping, cutting, bending and welding.

We offer a wide range of CNC machining services including milling and turning of various materials, as well as drilling, tapping, EDM (Electrical Discharge Machining), and wire EDM.

Sheet metal fabrication relies on a special set of tools across its cutting, welding bending, punching and joining processes to force the metal into the desired shape.

Online Message

If you are interested in cooperation, please contact us immediately and we will give you feedback as soon as possible!